Precision Laser Cutting Services China – Custom Laser Cut Parts Manufacturer & Fabrication Company

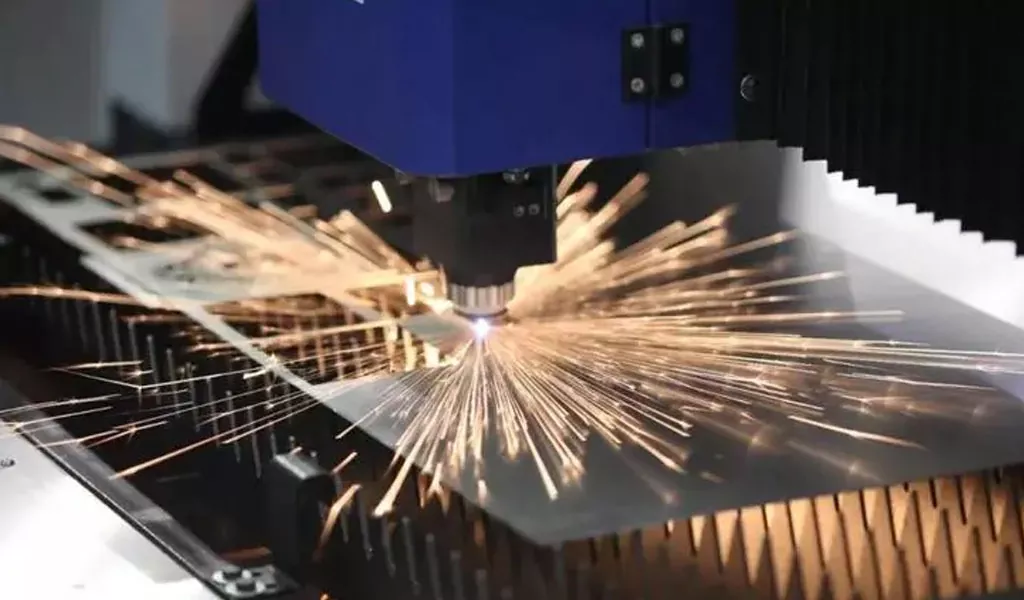

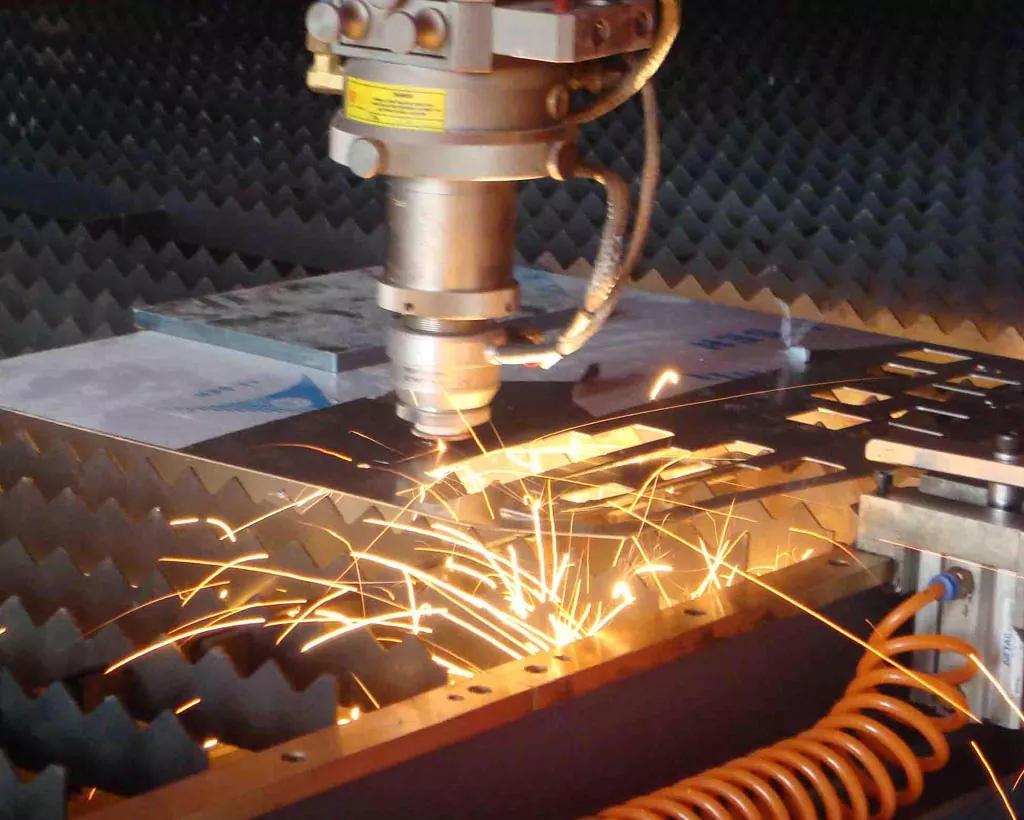

Need precision Laser Cutting components? With over 30 years of experience, Be-Cu has grown into a reliable expert sheet metal laser cutting company that offers quick-turn precision sheet metal cutting services, involves Fiber Laser Cutting, Co2 Laser Cutting and 3D Laser Cutting processes. Multiple laser cutter including 7 axis laser cutter, Gantry Laser Cutting Machine, CNC cutter, drills, and advanced measuring equipment ensure our in-house capacity to deliver your laser cutting parts with the most competitive prices, short lead time and on-time shipping.

We guarantee only the highest quality materials are used in all our projects and have a stringent quality control process to make sure that each product meets the standards set by our quality assurance department. From simple prototypes to full production runs, our Laser Cutting services can deliver reliable results on time and within budget. The accuracy tolerance for positioning is +/- 0.1 mm. Thermal effects on the material are small, therefore it is possible to cut small holes with a minimum diameter of 1/2 the material thickness as well as holes that can be threaded after cutting without requiring additional machining. The cutting line width it is smaller than 0.5 mm for most materials.We can be your perfect choice to get great designs and custom according to your designs using our Laser Cutting service.

Why Choose Our Laser Cutting Services

- A wide selection of metal materials in stock

- Specialist in laser cut parts fabrication with accurate dimension, tight tolerance and high precision

- Online laser cut design service and CAD file review to accelerate product development and save cost

- Quick reply and feedback to deal with any problems you have with the product drawing

- ISO9001:2015 certification and strict quality control system throughout each stage

- Average 7 days turnaround time and 99.85% on time delivery

- Applicable in broad industries from aerospace, automotive, medical to military, food, electronics, etc.

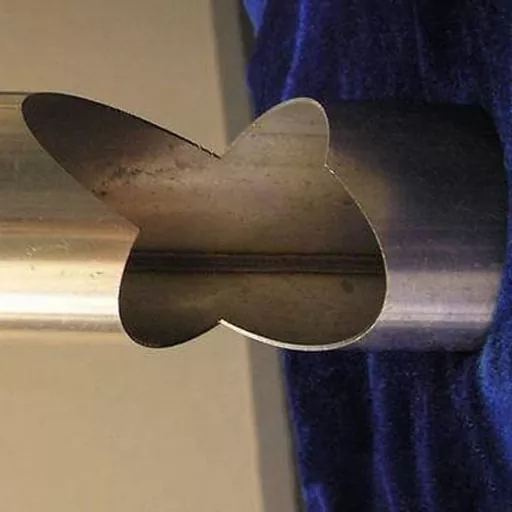

Custom Laser Cutting Services Capabilities

Work with our Laser Cutting services, a variety of production techniques will be employed to realize your expectations on the final Laser Cutting parts.

| Capabilities | Tube Laser Cutting | Plate Laser Cutting |

|---|---|---|

| Maximum Cut length | Up to 8.5 m with automatic loading | Up to 15 m with automatic loading |

| Diameter | Up to Ø240 mm | Up to Ø2500 mm |

| Box section | Up to 240 mm diagonal | ≤6500 x 2500 mm |

| Laser sources | Up to 4 kW | Up to 7 kW |

| Positioning accuracy | Pa:+/- 0.2 mm | Pa:+/- 0.2 mm |

| Maximum wall thickness | ≤12 mm | ≤12 mm |

Laser Cutting Materials Capabilities

We stock more than 50 types of high-quality metal cut materials for laser cut components used in various industries.

| Maximum Material | Thickness | Cutting Area | Laser Sources | Repeatability | Positioning Accuracy |

|---|---|---|---|---|---|

| Carbon Steel | ≤30 mm | ≤6500 x 2500 mm | Fibre & CO2 lasers up to 12 kW | Ps: +/- 0.05 mm | Pa: +/- 0.1 mm |

| Stainless Steel | ≤30 mm | ≤6500 x 2500 mm | Fibre & CO2 lasers up to 12 kW | Ps: +/- 0.05 mm | Pa: +/- 0.1 mm |

| Aluminium | ≤30 mm | ≤6500 x 2500 mm | Fibre & CO2 lasers up to 12 kW | Ps: +/- 0.05 mm | Pa: +/- 0.1 mm |

| Copper Alloys | ≤12 mm | ≤6500 x 2500 mm | Fibre & CO2 lasers up to 12 kW | Ps: +/- 0.05 mm | Pa: +/- 0.1 mm |

Metal Surface Finishing Services for Laser Cutting Parts

For the best surface quality for your Laser Cutting and sheet metal fabrication parts, a series of surface treatment services are provided for selection. More than the following surface finishes are available if you have other needs.

| Surface Treatment | Features |

|---|---|

| Polishing | a finishing process through which to smooth the surface of an object using an abrasive or a work wheel |

| Sand Blasting | also known as sandblasting or abrasive blasting, is a process of applying high pressure to push solid particles across the object surface at high speed to alter the surface roughness |

| Color Electrophoresis | applying different colors on metal materials and products through electrophoresis techniques |

| Pad Printing | special printing methods to transfer the color and image that you wanted on surfaces |

| Rubber Casting | provide waterproofing for laser cutting parts and sheet metak fabrication parts in varying applications, available in different colors |

| Silk Screen Printing | involves printing ink through stencils, applying for hardware products |

| Anodizing | forming a thin layer of aluminum oxide on the exterior of laser cutting parts to increase the thickness and corrosion resistance |

| Plating | including chrome plating, nickel plating and more, to change the properties of the metal surface or build up thickness for undersized parts. |

| Passivation | use a light coat of protective material to create a shell for enhancing the corrosion resistance or reducing the chemical reactivity. |