Sheet Metal Welding Service China – Custom Welding Parts Manufacturer

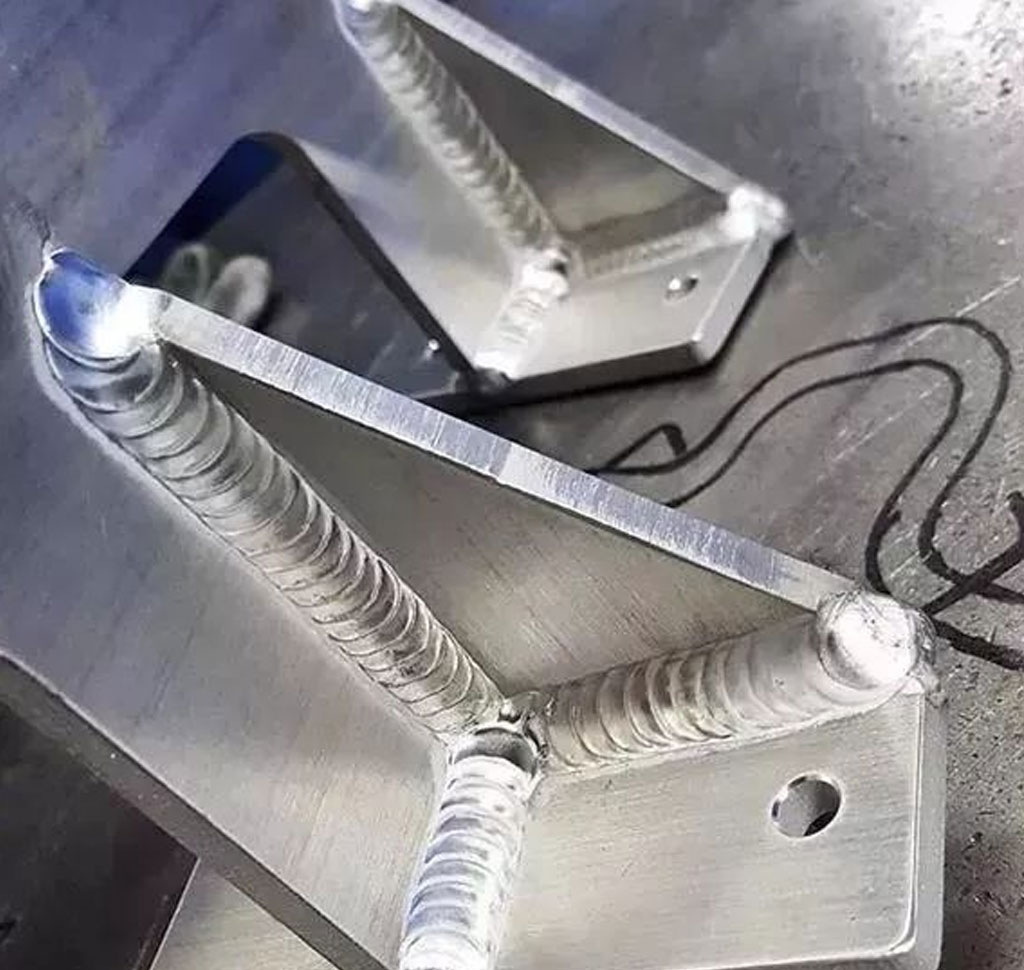

Be-Cu is a leading provider of high-quality sheet metal welding services. With over 30 years of experience in the industry, we have earned a reputation for excellence in craftsmanship, precision, and customer satisfaction. Our commitment to innovation, state-of-the-art technology, and a highly skilled workforce sets us apart as a trusted partner for all your sheet metal welding needs.

At Be-Cu, our mission is to deliver exceptional sheet metal welding services that exceed our customers’ expectations.ISO 9001:2015 certified welding services including gas metal arc welding (GMAW), MIG and TIG welding. Other welding services include robotic, wire feeder and pulse. Assembling, designing and development, CNC lathe cutting and machining, burnishing, precision machining, metal fabricating and hobbing services are also available.

Robotic welding services for original equipment manufacturers (OEMs).Capabilities include NC/CNC programming, CAD/CAM designing, 2D/3D modeling and prototyping. Meet CSA W47.1 standards. We are dedicated to providing cost-effective, durable, and aesthetically pleasing welding solutions while maintaining the highest standards of quality and safety.Works with impact-resistant, quenched, tempered, and stainless steel, aluminum, carbon steel, cast metals & alloys. Capable of welding medium and large-size metal components. Serves the railway, mining, oil and gas, construction, power, military, forestry, and agriculture industries. Suitable for enclosures, chassis and weldments applications. Blanket orders are accepted.

No matter what your project requires, our team has the skills and expertise needed to deliver exceptional precision sheet metal manufacturing results. We take great pride in the quality of our work and our ability to exceed customer expectations.

Why Choose Our Welding Service

- Be-Cu has full sheet metal welding capabilities including MIG, TIG, Flux Core and Pulse arc welding on mild steel, stainless steels, and aluminum.

- Trust us to tackle a wide variety of your welding projects, no matter how large or small your quantities.

- Our sheet metal welding services provide consistent, reliable welds, delivered on time. Choose from manual or robotic welding.

- ISO9001:2015 certification and strict quality control system throughout each stage

- Average 7 days turnaround time and 99.85% on time delivery

- Applicable in broad industries from aerospace, automotive, medical to military, food, electronics, etc.

Custom Sheet Metal Welding Services Capabilities

Work with our Sheet Metal Welding services, a variety of production techniques will be employed to realize your expectations on the final Sheet Metal Welding parts.

| Type | Advantage | Disadvantage |

|---|---|---|

| MIG welding – Gas Metal Arc Welding (GMAW) | MIG is great for welding large and thick materials quickly. It is the most beginner-friendly type of welding. | MIG welds are not as precise, strong, or clean not as TIG welds. The workpiece materials must be completely clean of any rust or slag. |

| TIG welding – Gas Tungsten Arc Welding (GTAW) | TIG is highly precise and versatile, allowing you to join a wide range of small and thin materials. It is great for welding non-ferrous metals. | TIG welding is more difficult to learn, making it a slower process with longer lead times and greater production cost. |

| Stick Welding – Shielded Metal Arc Welding (SMAW) | Stick welding is very versatile, inexpensive to start, and easy to learn. It can be used on a variety of metal alloys. | Consumable electrodes have to be frequently replaced and slag must be chipped away after welding, making it a slower process. |

| Flux Welding – Cored Arc Welding (FCAW) | Flux welding does not use shielding gas, so it can be used outdoors and in windy conditions. It can also be used on a variety of metal alloys. | The filler material is more expensive, compared to other types of arc welding. It also generates more fumes and smoke than other types of arc welding. |

MIG Welding Service

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a welding process that uses a non-consumable tungsten electrode to create a weld joint. It is known for its precision and versatility, making it suitable for various materials, including metals like steel, stainless steel, aluminum, and more. TIG welding produces high-quality, clean welds and is often used in applications where weld appearance and integrity are crucial, such as aerospace, automotive, and the food industry.

If you are looking for a TIG welding service, Be-Cu Is best choose for you, Capable of handling parts up to 2 in. plate and 11 in. rolled ring sizes and welding parts up to 14 in. dia. and 25 ft. length, width or height with +/- 0.002 in. tolerance. Prototypes and medium production volumes are available.Whether you need TIG welding for a small repair or a large-scale fabrication project, choose be-cu.com to ensure the success of your project.

TIG Welding Service

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a welding process that uses a non-consumable tungsten electrode to create a weld joint. It is known for its precision and versatility, making it suitable for various materials, including metals like steel, stainless steel, aluminum, and more. TIG welding produces high-quality, clean welds and is often used in applications where weld appearance and integrity are crucial, such as aerospace, automotive, and the food industry.

If you are looking for a TIG welding service, Be-Cu Is best choose for you, Capable of handling parts up to 2 in. plate and 11 in. rolled ring sizes and welding parts up to 14 in. dia. and 25 ft. length, width or height with +/- 0.002 in. tolerance. Prototypes and medium production volumes are available.Whether you need TIG welding for a small repair or a large-scale fabrication project, choose be-cu.com to ensure the success of your project.

Metal Surface Finishing Services for Industry Welding Parts

For the best surface quality for your Welding and sheet metal fabrication parts, a series of surface treatment services are provided for selection. More than the following surface finishes are available if you have other needs.

| Surface Treatment | Features |

|---|---|

| Polishing | a finishing process through which to smooth the surface of an object using an abrasive or a work wheel |

| Sand Blasting | also known as sandblasting or abrasive blasting, is a process of applying high pressure to push solid particles across the object surface at high speed to alter the surface roughness |

| Color Electrophoresis | applying different colors on metal materials and products through electrophoresis techniques |

| Pad Printing | special printing methods to transfer the color and image that you wanted on surfaces |

| Rubber Casting | provide waterproofing for laser cutting parts and sheet metak fabrication parts in varying applications, available in different colors |

| Silk Screen Printing | involves printing ink through stencils, applying for hardware products |

| Anodizing | forming a thin layer of aluminum oxide on the exterior of laser cutting parts to increase the thickness and corrosion resistance |

| Plating | including chrome plating, nickel plating and more, to change the properties of the metal surface or build up thickness for undersized parts. |

| Passivation | use a light coat of protective material to create a shell for enhancing the corrosion resistance or reducing the chemical reactivity. |