Premier Online Custom Sheet Metal Bending Manufacturer In China

At Be-Cu, we take pride in being a leading innovator and manufacturer in the world of sheet metal bending. With a rich history of craftsmanship and a commitment to cutting-edge technology, we have established ourselves as a trusted partner for industries requiring precision sheet metal solutions.

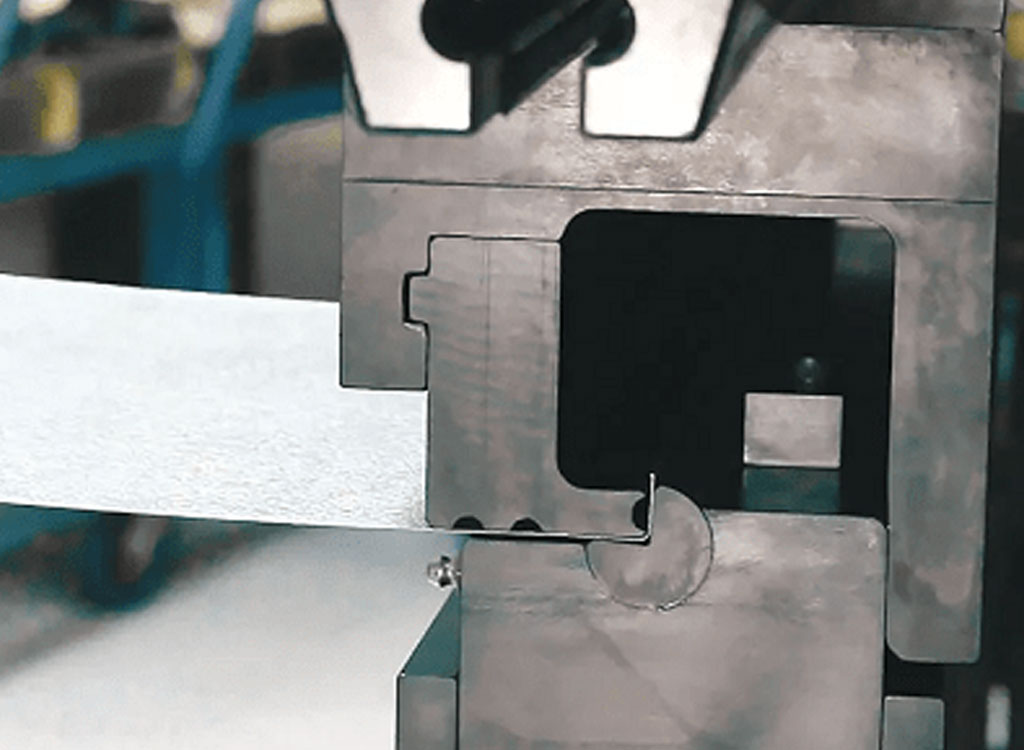

With 30 years of experience, our team of highly skilled engineers and technicians possesses a deep understanding of sheet metal fabrication. We specialize in bending and forming various metals, ranging from stainless steel and aluminum to copper and brass. Our expertise extends to a wide array of industries, including aerospace, automotive, electronics, architecture, and beyond.To ensure the highest quality products, we have invested heavily in state-of-the-art machinery and equipment. Our modern production facilities are equipped with the latest CNC bending machines, laser cutters, and quality control systems. This allows us to consistently meet the most demanding specifications and tight tolerances required by our customers.

Sheet metal bending services. Capable of bending sheet parts up to 120 in. sizes and +/-0.03 in. tolerance. Also, capable of bending tubing parts from 1/8 to 7 in. OD. Sheet metal wall thickness ranges from 1/32 to 3/8 in. and steel bar and strip thickness ranges from 1/8 to 6 in. Prototype and low to high-volume production runs are available. Applications include bowling ball racks, candle stands, fitness machine equipment, lamps, and tables. Serves the advertising, aerospace, agricultural, and alternative energy industries. Blanket orders, AutoCAD, and SolidWorks® files are accepted. Meets Mil-Spec, AS, and ANSI standards. RoHS compliant. FDA approved.Secondary services include aqueous cleaning, coping, beading, drilling, flattening, flaring, notching, piercing, slotting, swaging, threading, bar coding, brush & tumble deburring, chamfering, JIT-SPC, plating, powder coating, reverse engineering, packaging & assembly.

Whether you have a complex sheet metal bending project in mind or need expert advice on material selection and design, we are here to assist you. We invite you to reach out to us to discuss your requirements, explore our capabilities, and discover how Be-Cu prototype can be your trusted partner in sheet metal bending.Thank you for considering Be-Cu prototype as your sheet metal bending manufacturer. We look forward to the opportunity to serve your needs and exceed your expectations.Contact us today to start a conversation about your project!

Why Choose Our CNC Bending Service

- As long as your part has a maximum flat size of 44” x 30” and is no thicker than .250,” depending on length, we can bend it.

- All our services come guaranteed. If you’re not 100% happy with your parts, we’ll give you a refund or remake on the spot.

- Our sheet metal bending services provide consistent, reliable welds, delivered on time. Choose from manual or robotic welding.

- ISO9001:2015 certification and strict quality control system throughout each stage

- Average 7 days turnaround time and 99.85% on time delivery

- Applicable in broad industries from aerospace, automotive, medical to military, food, electronics, etc.

Custom Sheet Metal Bending Services Capabilities

Work with our Sheet Metal Bending services, a variety of production techniques will be employed to realize your expectations on the final Sheet Metal Bending parts..What Standards Of Metal Bending Services Can We Provide?

| Standards | Description | ||

|---|---|---|---|

| Maximum power | 13KVA | 10.5KVA | 7.5KVA |

| Maximum Part Size | 3100*3100MM | 3100*3100MM | 2500*2500MM |

| Metal Bending Forces | 1500KN | 1000KN | 800KN |

| Bending Line Length | 3100MM | 3100MM | 2500MM |

| Bending Thickness | 6MM | 4MM | 3MM |

| General Tolerances | ±0.2MM | ±0.2MM | ±0.2MM |

| Bend Radius | >1MM | >1MM | >1MM |

| Bend Angle | >35° | >35° | >35° |

Metal Surface Finishing Services for Sheet Metal Bending Parts

For the best surface quality for your Sheet Metal Bending and sheet metal fabrication parts, a series of surface treatment services are provided for selection. More than the following surface finishes are available if you have other needs.

| Surface Treatment | Features |

|---|---|

| Polishing | a finishing process through which to smooth the surface of an object using an abrasive or a work wheel |

| Sand Blasting | also known as sandblasting or abrasive blasting, is a process of applying high pressure to push solid particles across the object surface at high speed to alter the surface roughness |

| Color Electrophoresis | applying different colors on metal materials and products through electrophoresis techniques |

| Pad Printing | special printing methods to transfer the color and image that you wanted on surfaces |

| Rubber Casting | provide waterproofing for laser cutting parts and sheet metak fabrication parts in varying applications, available in different colors |

| Silk Screen Printing | involves printing ink through stencils, applying for hardware products |

| Anodizing | forming a thin layer of aluminum oxide on the exterior of laser cutting parts to increase the thickness and corrosion resistance |

| Plating | including chrome plating, nickel plating and more, to change the properties of the metal surface or build up thickness for undersized parts. |

| Passivation | use a light coat of protective material to create a shell for enhancing the corrosion resistance or reducing the chemical reactivity. |