Manufacturing metal parts is a precise and intricate process that requires careful planning and execution. One of the key factors in metal part production is the configuration of various components. Whether you’re working on a custom project or mass-producing parts, understanding how to configure metal components efficiently can save time, resources, and ultimately lead to a better final product. In this article, we will explore the concept of metal part configuration and break it down into four simple steps that anyone can follow to achieve success in metalworking.

Step 1: Define Your Requirements

The first step in metal part configuration is defining your requirements. This involves a clear understanding of the purpose and specifications of the metal part you intend to create. What are the material requirements, size, shape, and functionality of the part? Consider the environmental conditions it will be subjected to and any regulatory standards it must meet. Defining these requirements will serve as the foundation for your entire configuration process.

Step 2: Select the Appropriate Materials

Choosing the right materials for your metal part is crucial. Factors such as strength, durability, and corrosion resistance are all key considerations in material selection. Additionally, you need to factor in the cost of materials and their availability. Depending on your requirements, you may choose from various types of metals, including steel, aluminum, copper, or specialty alloys. Selecting the appropriate material is a critical decision that impacts the performance and longevity of your metal part.

Step 3: Design and Modeling

The design and modeling phase is where the magic happens. You need to create a detailed design of your metal part, including its dimensions, shape, and features. This is often done using computer-aided design (CAD) software, which allows for precise modeling and visualization. At this stage, consider factors such as manufacturability, assembly, and any necessary modifications to ensure your design is feasible and cost-effective.

Moreover, you might want to consult with engineers and experts in the field to ensure your design aligns with industry best practices and standards. This step is a critical component of the metal part configuration process, as it provides the blueprint for the manufacturing phase.

Step 4: Manufacturing and Quality Control

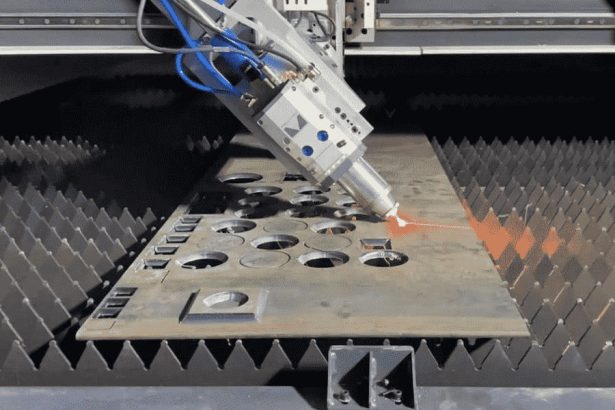

With a well-defined design and material selection in hand, it’s time to move on to the manufacturing phase. Depending on the complexity of your metal part, you may need to choose the appropriate manufacturing method, whether it’s machining, casting, forging, or 3D printing.

Throughout the manufacturing process, quality control measures are essential to ensure the final product meets the established requirements and specifications. This involves inspections, measurements, and testing to identify any defects or inconsistencies. Only by maintaining strict quality control can you guarantee the reliability and safety of your metal part.

Conclusion

In conclusion, configuring metal parts may seem complex, but by breaking the process down into four simple steps, it becomes more manageable. From defining your requirements and selecting the right materials to detailed design and thorough manufacturing, each step plays a crucial role in achieving success in metalworking. By following this guide, you can confidently tackle metal part configuration, leading to the creation of high-quality, functional, and reliable metal components. Whether you’re a professional engineer or a DIY enthusiast, these four steps will guide you toward success in your metalworking endeavors.

China Sheet Metal Fabrication Manufacturer

Custom precision metal fabrication services. Product specialties include UL® certified NEMA enclosures for various environmental conditions. Capabilities include punching, shearing, laser cutting, bending, machining, press brake forming, and welding. Materials worked with include mild steel, stainless steel, aluminum, brass, and more. Production volumes range from prototype to 10,000 pieces annually. Contract options include discrete orders, blanket orders, quarterly buys, and annual contracts. Value added services include inventory management, rapid prototyping, process development, design for manufacturability, inspection, supply chain management, transportation, and logistics. Industries served include aerospace, automotive, defense, electronic, electrical, entertainment, food and beverage, health, industrial automation, machinery, medical, oil, energy, power, sporting goods, telecommunications, transportation, and more.

using high quality materials

for your sheet metal parts orders

We uses a wide range of material selections for our sheet metal fabrication process. Among our materials are aluminum, stainless steel, brass, magnesium, copper, carbon steel, bronze, galvanized steel, and more. Each material is available in different grades and varieties. Rest assured that all the materials used for your sheet metal parts are durable, corrosion-resistant, long-lasting, rust-proof, wear-resistant, and high-performance. If you want a specific material to be used in the sheet metal fabrication process, don’t hesitate to contact us!

- Carbon Steel

- Stainless Steel

- Aluminum

- Brass

- Copper

- Magnesium

- Bronze

- Galvanized Steel

Why BE-CU is Trusted by 1000+ Clients

Our sheet metal fabrication covers a lot of benefits to many industries, businesses, or projects. Below are the advantages of our services.

- Affordable and Fast Production:We can quickly produce different sheet metal prototypes and final products. KDM offers speedy production while assuring high precision. Our high-volume production also allows us to have cost-effect sheet metal fabrication services.

- Excellent Strength to Weight Ratio:Through our advanced sheet metal fabrication, we can produce sheet metal parts that are lightweight yet durable. We assure high strength, scratch resistance, and corrosion resistance to all produced sheet metal products.

- Wide Range of Materials and Techniques Used:We are experts in different sheet metal fabrication techniques that allow us to produce complex parts with additional intricate features such as notches, slots, holes, etc. Our wide range of sheet metal materials can also withstand electrical, high heat, corrosion, and more.

Online Contact China Precision Sheet Metal Manufacturers

As a direct supplier of precision machined and finished complete components to all segments of the aerospace, semiconductor, automotive, and medical industries, including innovative high tech startups, BE-CU Sheet metal manufacturer is your trusted source for precision sheet metal fabrication services.

To learn more about our aluminum,stainless steel and other steel alloy sheet metal fabrication services, contact us, or give us a call at +86 153 8731 8440, and one of our expert associates will assist you. BE-CU is your trusted source for premium sheet metal fabrication services and metal spinning china manufacturer.