Custom Electronic Sheet Metal Fabrication

Be-Cu Company is ideally situated in a rural area, on our own land, and our recent expansion and the new sheet metal electronics, custom machined sheet metal electronic parts and semiconductor manufacturing systems that we have added are just a email call away from helping you with your current project involving electronics or semiconductors.

We utilize our electronics sheet metal fabrication shop and have been producing top-notch documentation and processes for all of your electronics, semiconductor manufacturing, custom machined parts and CNC parts needs for almost 30 years

Our customers know us as a Sheet Metal Fabrication manufacturer of quality, reasonably-priced semiconductors and other electronic parts with exceptional customer care.Equipped with an ISO 9001- and AS9100-certified facility and with over 30 years of utilizing custom machine parts, Be-Cu is on the cutting edge of companies that produce sheet metal manufacturing electronics and electronics components.

To find out more about us — or to tell us about your project — email us now at [email protected] or contact us here to get your free quote!We are entrusted with the custom electronic sheet metal parts of top global companies. Experience why they keep coming back to Be-Cu for their sheet metal parts.

| Processes | Laser Cutting/CNC Bending/Welding etc |

| Lead Time | As fast as 7 days |

| Finishing Options | Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating, Vibratory Tumbling |

| Tolerance | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

| Applications | Electronic |

| Alloys | Aluminum,Stainless Steel,Copper,Titanium,Brass etc., |

Having developed a deep understanding of the key issues and dynamics that govern multiple industries and functional expertise, we are able to provide strategic advice to our clients helping them to acquire substantive business results of both a financial and operational nature.

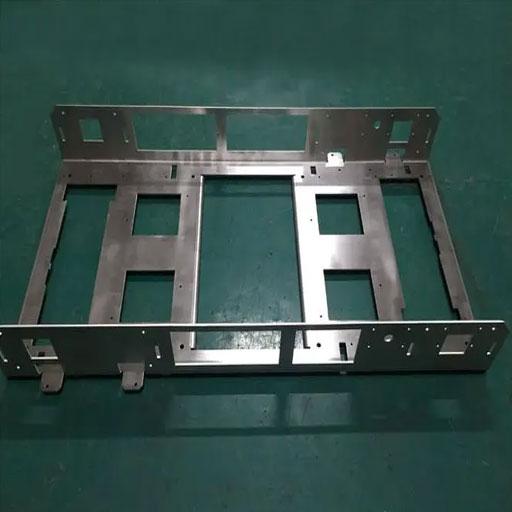

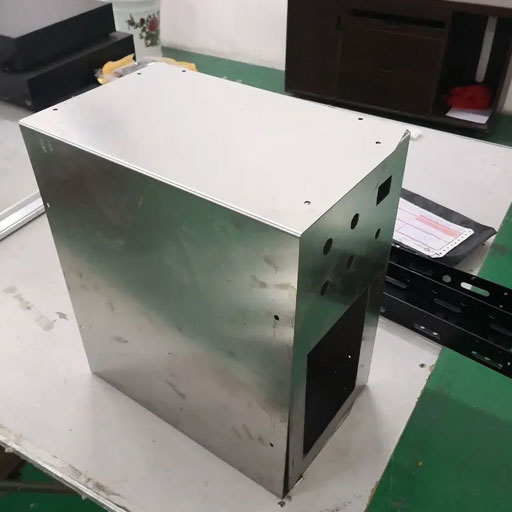

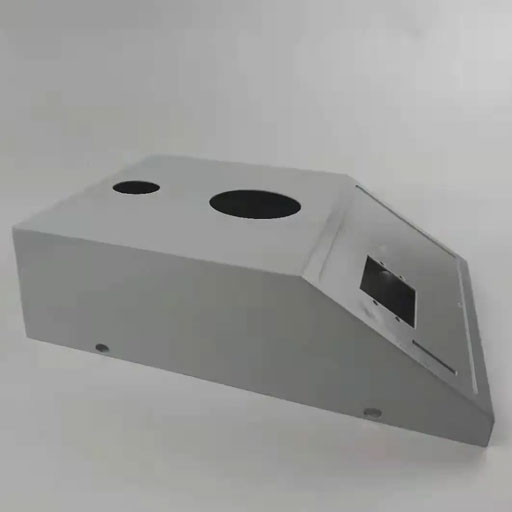

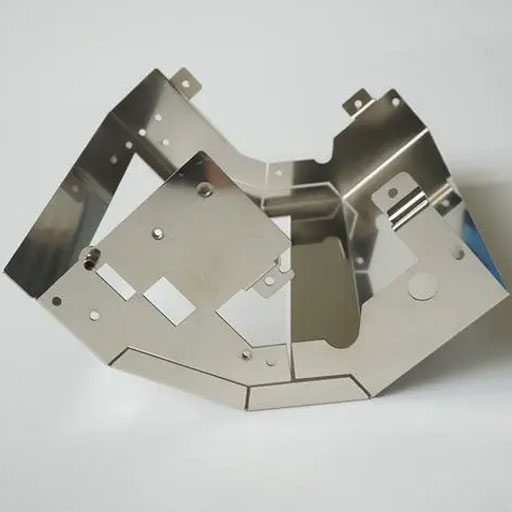

Commonly Sheet Metal Fabrication Electronic Components

Sheet metal fabrication is a versatile process used to create a wide range of electronic components and enclosures. These components are commonly found in various industries, including electronics, telecommunications, automotive, aerospace, and more. Here are some commonly fabricated sheet metal electronic components:

- Chassis and Enclosures: Sheet metal is often used to create protective enclosures and chassis for electronic devices. These enclosures shield the internal components from environmental factors and electromagnetic interference (EMI).

- Racks and Cabinets: Sheet metal racks and cabinets are used to house servers, networking equipment, and other electronic hardware in data centers and telecommunications facilities.

- Front Panels: Front panels of electronic devices often feature sheet metal construction, providing a professional appearance and durability.

- Mounting Brackets: Sheet metal brackets are used for mounting various electronic components, such as power supplies, circuit boards, and connectors, within devices or enclosures.

- Heat Sinks: Heat sinks are crucial for dissipating heat generated by electronic components. Sheet metal heat sinks can be designed with fins or other heat-dissipating features to improve cooling.

- Electromagnetic Shields: Sheet metal is used to create electromagnetic shields or Faraday cages that protect sensitive electronic components from electromagnetic interference.

- Cable Trays and Ducts: Sheet metal cable trays and ducts are used for organizing and protecting cables within electronic enclosures or buildings.

- Connectors and Mounting Plates: Sheet metal is often used to fabricate mounting plates and connector panels for connecting cables and wires to electronic devices.

- Rack-Mountable Shelves: These shelves are used to support and organize electronic equipment within standard 19-inch racks commonly found in data centers and server rooms.

- Bus Bars: Sheet metal bus bars are used to distribute electrical power within electronic systems and are commonly found in power distribution units (PDUs) and circuit breaker panels.

- EMI/RFI Shields: Electronic components sensitive to electromagnetic or radio-frequency interference require EMI/RFI shields, which are typically made of sheet metal with specialized designs.

- Louvers and Vents: Sheet metal louvers and vents are used for ventilation and cooling purposes in electronic enclosures to prevent overheating.

- Rack Handles and Rails: Sheet metal handles and rails are commonly used in server racks and cabinets to facilitate equipment installation and maintenance.

- Battery Trays and Holders: Sheet metal is used to create trays and holders for batteries in various electronic devices, such as uninterruptible power supplies (UPS) and portable electronics.

- Component Brackets: Sheet metal brackets are used to secure and support individual electronic components within larger assemblies.

Sheet metal fabrication techniques include cutting, bending, welding, and finishing processes like powder coating or painting. These processes allow for the creation of custom electronic components that meet specific design and functionality requirements.

Case Studies

Sheet Metal Elecronics and Parts in Semiconductor Manufacturing

Sheet metal plays a crucial role in semiconductor manufacturing, where precision and cleanliness are paramount. It is used to create a wide range of specialized components and parts necessary for the production, testing, and handling of semiconductor wafers and microelectronics. Here are some sheet metal electronics and parts commonly used in semiconductor manufacturing:

- Wafer Carriers: Sheet metal is used to fabricate wafer carriers that hold and transport semiconductor wafers during various stages of the manufacturing process. These carriers need to be clean, precise, and compatible with cleanroom environments.

- Test Sockets: Sheet metal test sockets are used to test semiconductor devices. These sockets provide electrical connections to the device under test and are essential for quality control and performance testing.

- Lead Frames: Lead frames are used in the packaging of semiconductor devices. Sheet metal lead frames are designed to provide electrical connections between the semiconductor die and the external package, ensuring reliable electrical connections.

- Enclosures for Semiconductor Equipment: Many semiconductor manufacturing machines and equipment require protective enclosures made of sheet metal to shield sensitive components from environmental contamination and to maintain cleanroom conditions.

- Cleanroom Equipment and Furniture: Sheet metal is used to create cleanroom-compatible equipment and furniture, including storage cabinets, workstations, and racks for semiconductor manufacturing facilities.

- Gas and Chemical Delivery Systems: Sheet metal components are used in the construction of gas and chemical delivery systems that supply the precise gases and chemicals required for semiconductor processing.

- Ion Implantation Shields: In ion implantation processes, sheet metal shields are used to precisely direct ions onto semiconductor wafers to create the desired electrical properties.

- Chambers and Enclosures for Etching and Deposition: Sheet metal enclosures and chambers are integral to processes such as chemical vapor deposition (CVD) and etching, where the deposition or removal of materials occurs in a controlled environment.

- Vacuum Chamber Components: In vacuum processes like physical vapor deposition (PVD), sheet metal is used to create components such as deposition chambers, shields, and holders.

- Cleanroom Fixtures: Custom sheet metal fixtures are used to securely hold and manipulate delicate semiconductor components during manufacturing and testing.

- Electrostatic Chucks (ESCs): Sheet metal is used to create components of ESCs that securely hold and position semiconductor wafers during semiconductor processing steps.

- Gas Panels: Gas panels made from sheet metal are used to control the flow and distribution of gases in semiconductor manufacturing processes.

- Heat Exchangers: Sheet metal heat exchangers are used for temperature control in semiconductor equipment and processes.

- Electroplating Racks: For processes like wafer electroplating, sheet metal racks are used to hold and position the wafers.

- Ion Beam Lithography Components: Sheet metal components are used in ion beam lithography systems to direct ion beams for precision patterning on semiconductor wafers.

Semiconductor manufacturing requires extreme precision, cleanliness, and control over environmental factors. Sheet metal components in this industry are often made from materials like stainless steel and aluminum to meet these stringent requirements and maintain the integrity of semiconductor devices. Additionally, surface treatments and finishes are carefully applied to minimize contamination and maintain cleanroom compatibility.

Electronic Sheet Metal Manufacturing & Capabilities

Our precision sheet metal fabriction capabilities include in-house, full-service manufacturing for all metal components. Our state-of-the-art metal working equipment and technology include:

- 7-axis (3D) and flat (2D) CNC Laser Cutter: Tolerance ranges from +/-0.001 in. to +/-0.005 in.Capable of handling sheets and plates with 16 gauge to 1.25 in. thickness, 20 to 90 ft. length and 7 to 12 ft. width.7 axis tube laser services available for up to 6 inch square and round tube.

- CNC Bending Machine : Bending plate up to 12 ft. width with 3/8 in. thickness. Bending tube parts from 1 1/2 to 3 1/2 in. sizes.

- Welding Machine: Welding assemblies with up to 24 ft. length and 92 in. dia.

- Quality Control: Temperature controlled inspection room with CMM and manual inspection capabilities.

- Software: Full 5-axis CAM system with machine simulation. We use Hypermill, Solidworks, MasterCAM, PC-DMIS CAD++ and Shoptech E2 Shop Management software.

Be-Cu- Expert Sheet Metal Electronic Parts Manufacturer

If you want to grow your sheet metal Electronic Parts business, Be-Cu Manufacturer in China is your one-stop solution choice. Develop your designs with reliable sheet metal fabrication car Parts Factory services in China. Equipped with advanced machines, our general tolerance is +/-0.01mm, and with high precision laser cutter in-house, we can fabrication your high accuracy and complex sheet metal products.

Be-Cu prototype is an expert Sheet Metal Electronic Parts manufacturer in China since 1995. We dedicate to sheet metal fabrication parts and the production of Sheet Metal Electronic Components. Be-Cu has accumulated rich experience, inherits the advanced industrial concept, and owned a professional design team and first-class Sheet Metal Electronic Parts types of equipment.