Powder coating is a type of coating that is applied as a dry powder to the surface of materials, primarily metals, using electrostatic force. Unlike conventional liquid paints, powder coatings do not require a solvent to keep the binder and filler parts in a liquid suspension form. After application, the powder is cured under heat to form a hard finish that is both durable and visually appealing. In healthcare equipment applications, powder coating plays a crucial role in enhancing both the functionality and aesthetics of medical devices, instruments, and other critical equipment. This coating technology has become increasingly popular due to its superior performance in providing corrosion resistance, durability, and an improved finish, all while being environmentally friendly.

Introduction to Powder Coating

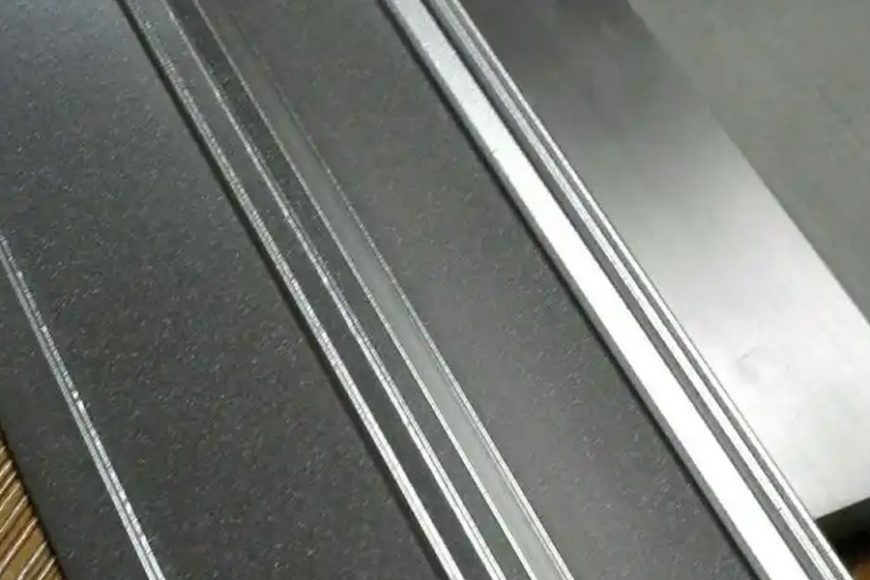

Powder coating is a widely used finishing process for a range of materials, particularly in the manufacturing of metal parts. The powder used in the process typically consists of pigments, resins, curing agents, and additives that, when heated and applied to the surface of a product, create a durable finish. The powder is applied using an electrostatic spray deposition (ESD) method, where the powder particles are electrically charged and attracted to the grounded surface of the substrate. Once the powder has been evenly distributed, it is baked in an oven at high temperatures, typically between 160 to 210°C (320 to 410°F), causing the powder to melt and fuse into a solid layer. This process creates a finish that is tougher and more resistant to chipping, scratching, and fading than traditional liquid coatings.

The Role of Powder Coating in Healthcare Equipment

Healthcare equipment, which includes a broad range of medical devices, hospital furniture, diagnostic instruments, surgical tools, and various other products, often requires specialized coatings to ensure safety, durability, and hygiene. The healthcare environment is demanding, with stringent requirements for equipment that is reliable, easy to clean, resistant to corrosion, and able to withstand frequent use in sterile environments. Powder coating provides a unique solution for meeting these requirements due to its combination of durability, aesthetics, and environmental benefits.

Durability and Resistance

One of the primary advantages of powder coating in healthcare equipment applications is its exceptional durability. Medical equipment is often subjected to harsh conditions, including constant handling, frequent cleaning, exposure to chemicals, and variations in temperature. Powder coatings are highly resistant to corrosion, which is particularly important in healthcare settings where equipment can be exposed to disinfectants, water, and other corrosive substances. This durability makes powder-coated surfaces ideal for medical devices such as hospital beds, wheelchairs, and examination tables, which require long-term reliability and minimal maintenance.

In addition to corrosion resistance, powder coatings offer high resistance to impacts, scratches, and abrasions. These qualities make powder-coated surfaces less likely to chip, wear, or degrade over time, even with the frequent handling and usage of medical equipment. This is crucial in healthcare environments where equipment is subject to constant use and frequent cleaning and sterilization.

Hygiene and Easy Cleaning

Hygiene is a critical concern in healthcare settings, where the risk of contamination can lead to the spread of infections and pose serious health risks to patients and healthcare workers. Medical equipment must not only be durable and functional but also easy to clean and sanitize. The smooth, non-porous finish provided by powder coating helps to reduce the accumulation of dirt, grime, and bacteria. Additionally, powder coatings are compatible with a variety of cleaning and disinfecting agents used in healthcare environments, ensuring that equipment can be properly sterilized without damaging the surface.

Powder coatings can be applied with a smooth or textured finish, depending on the specific needs of the equipment. The smooth finish is particularly beneficial for equipment that requires regular cleaning and sterilization, as it prevents the buildup of germs and contaminants. Textured finishes, on the other hand, can be useful for certain applications where grip or friction is necessary, such as handles or control panels on medical devices.

Aesthetic Appeal

The aesthetic qualities of healthcare equipment play an important role in creating a comfortable and positive environment for both patients and healthcare workers. Powder coatings are available in a wide range of colors and finishes, allowing manufacturers to produce aesthetically pleasing medical devices that meet the specific needs of healthcare settings. The ability to customize the color and texture of equipment through powder coating can help healthcare providers create visually appealing environments that promote patient comfort and satisfaction.

In addition to color and texture options, powder coating also enhances the visual appeal of medical equipment by providing a consistent and uniform finish. The smooth, glossy appearance achieved through powder coating can improve the overall look of healthcare products, contributing to a clean and professional aesthetic. This is particularly important for high-visibility items such as hospital beds, patient monitors, and diagnostic equipment.

Environmental and Safety Benefits

In recent years, there has been increasing pressure to adopt more environmentally friendly manufacturing processes, and powder coating offers a solution that addresses these concerns. Unlike traditional liquid paints, which contain solvents that release volatile organic compounds (VOCs) into the air, powder coatings are free of solvents and do not emit harmful fumes during application. This makes powder coating a safer and more environmentally responsible choice, particularly in industries like healthcare, where safety and sustainability are key considerations.

Powder coating also generates less waste than conventional liquid coatings. Because excess powder can be collected and reused, the material efficiency of the process is significantly higher, reducing both material costs and environmental impact. Furthermore, the high durability of powder-coated finishes means that healthcare equipment requires fewer touch-ups or replacements, contributing to a reduction in waste over the product’s lifecycle.

Types of Powder Coatings for Healthcare Equipment

Several types of powder coatings are used in healthcare equipment applications, each offering distinct properties and benefits. The two primary categories of powder coatings are thermoplastic and thermoset coatings, both of which are applied in similar ways but differ in terms of their chemical composition and curing processes.

Thermoplastic Powder Coatings

Thermoplastic powder coatings are made from resins that soften and flow when heated but do not undergo any chemical change during the curing process. These coatings can be remelted and reshaped if necessary, making them highly versatile for applications that require rework or repairs. Thermoplastic powders are typically more flexible and less brittle than thermoset powders, which makes them suitable for medical equipment that may need to withstand impact or movement. However, thermoplastic coatings may not be as resistant to high temperatures as thermoset coatings, so they are generally used in lower-temperature applications.

Thermoset Powder Coatings

Thermoset powder coatings, on the other hand, undergo a chemical change when heated, resulting in a hard, cross-linked structure that cannot be remelted. These coatings are typically more durable and resistant to high temperatures, making them ideal for healthcare equipment that may be exposed to heat during sterilization or disinfection. Thermoset coatings offer superior mechanical properties, including resistance to abrasion, impact, and corrosion. This makes them suitable for medical devices and equipment that need to maintain their integrity under frequent use and exposure to harsh conditions.

Specialty Powder Coatings

In addition to standard thermoplastic and thermoset powders, there are several specialty coatings designed to meet specific needs in healthcare applications. For example, antimicrobial powder coatings incorporate agents that inhibit the growth of bacteria, fungi, and other microorganisms, making them ideal for use in environments where infection control is critical. These coatings are especially useful in hospitals, clinics, and other healthcare facilities where minimizing the risk of cross-contamination is essential.

Another specialty coating is the anti-bacterial powder coating, which is designed to resist microbial growth. This feature is particularly useful in medical settings where hygiene is a top priority. By incorporating antimicrobial agents into the coating, manufacturers can reduce the risk of bacteria or viruses adhering to the surfaces of medical devices, thus helping to reduce the potential spread of infections.

Applications of Powder Coating in Healthcare Equipment

Powder coating has found widespread application in healthcare equipment due to its ability to meet the stringent requirements for safety, hygiene, and durability. Common healthcare equipment that benefits from powder coating includes:

Hospital Furniture

Hospital beds, examination tables, patient chairs, and other types of hospital furniture are often powder-coated to provide a durable and hygienic surface. The powder coating protects the metal frame of the furniture from corrosion and wear, while also providing an easy-to-clean surface that can withstand frequent disinfection.

Medical Instruments

Surgical instruments, diagnostic tools, and other medical devices often require powder coating to ensure that they are both durable and resistant to corrosion. The coating also ensures that the instruments remain clean and free from contaminants after frequent sterilization processes.

Healthcare Equipment Frames and Casings

Medical equipment such as patient monitoring devices, wheelchairs, and imaging machines often have metal frames or casings that benefit from powder coating. The coating protects the metal components from rust and damage, ensuring that the equipment remains functional and reliable over time.

Wheelchairs and Mobility Aids

Wheelchairs, walking aids, and other mobility equipment used by patients in healthcare settings often feature powder-coated frames for durability and hygiene. The coating provides resistance to corrosion, scratches, and wear, ensuring that these devices remain in optimal condition despite frequent use.

Storage Solutions

Storage units, such as shelving and carts used in healthcare facilities, are commonly powder-coated to prevent rust and provide a clean, easy-to-maintain surface. These storage solutions must withstand constant handling and exposure to disinfectants, making powder coating an ideal choice for ensuring long-lasting performance.

Conclusion

Powder coating has proven to be an essential technology in healthcare equipment manufacturing due to its ability to provide durable, hygienic, and aesthetically pleasing finishes. From corrosion resistance to ease of cleaning, powder-coated surfaces meet the demanding requirements of healthcare environments where functionality and safety are paramount. As the healthcare industry continues to evolve, the use of powder coating will likely increase, driven by its environmental benefits, cost-effectiveness, and superior performance in critical applications. With its wide range of applications in medical devices, hospital furniture, mobility aids, and more, powder coating remains an indispensable part of modern healthcare equipment manufacturing.