The ultra-fine stepped shaft is a shaft part with a special shape, which is characterized by multiple stepped transition areas on the shaft body. Such parts are commonly used in precision instruments, optical equipment, electronic products and other fields, requiring high precision and smooth surfaces. This article will introduce the processing method of ultra-fine stepped shafts, including micro manufacturing techniques and precautions, to help readers understand the process and achieve high-quality processing results.

Precision Manufacturing Technology

- (1) Raw material preparation: Choose high-quality metal materials, such as stainless steel or aluminum alloy, to ensure the uniformity and stability of the material.

- (2) Turning processing: Use a lathe for turning processing, and perform rough turning and finishing operations in sequence according to the design requirements. By controlling the cutting speed, feed rate and cutting tool selection, the shape and size of the steps can be accurately cut.

- (3) Grinding: Use a grinder for grinding to improve surface finish and dimensional accuracy. Use a grinding wheel for grinding and adjust grinding parameters such as grinding speed, feed rate and grinding wheel selection as needed.

- (4) Polishing treatment: The step shaft is surface treated through a polishing process to improve the finish and touch. Use fine sandpaper or a polishing cloth to polish by hand or mechanically to bring the surface to the desired smoothness.

Precautions

- (1) Process control: During the processing process, various processing parameters need to be strictly controlled, such as cutting speed, feed speed, selection of cutting tools and use of cutting fluid. This ensures the stability of processing quality and dimensional accuracy.

- (2) Surface quality: During the processing of ultra-fine step shafts, surface quality is very important. During the turning and grinding process, attention should be paid to the wear of cutting tools and grinding tools, and they should be replaced or repaired in time to ensure the smoothness and flatness of the processed surface.

- (3) Measurement and inspection: After processing is completed, appropriate measuring tools need to be used to inspect the dimensions of the ultra-fine step shaft to ensure that it meets the design requirements. Precision measuring tools such as micrometers, microscopes or three-dimensional coordinate measuring machines can be used to measure to ensure the accuracy and consistency of processing.

In Conclusion

The processing of ultra-fine step shafts requires precise turning and grinding processes, and strict control of processing parameters and surface quality. Reasonable selection of processing tools and measuring tools and strengthening quality control can ensure the high quality and stability of ultra-fine step shafts. During the processing, attention should be paid to process control and measurement inspection to ensure that the processing results meet the design requirements. Through reasonable processing methods and strict quality control, precise processing of ultra-fine step shafts can be achieved to meet the needs of various applications.

China Sheet Metal Fabrication Manufacturer

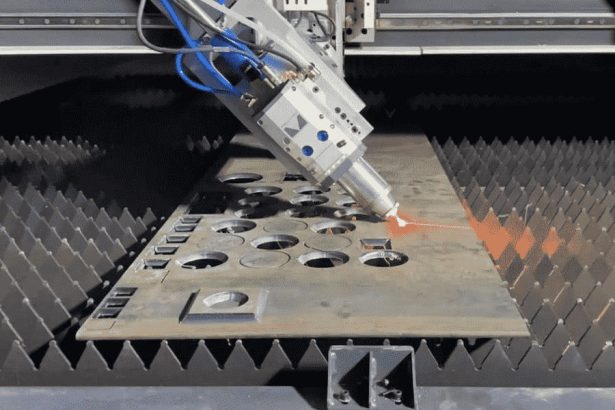

Custom precision metal fabrication services. Product specialties include UL® certified NEMA enclosures for various environmental conditions. Capabilities include punching, shearing, laser cutting, bending, machining, press brake forming, and welding. Materials worked with include mild steel, stainless steel, aluminum, brass, and more. Production volumes range from prototype to 10,000 pieces annually. Contract options include discrete orders, blanket orders, quarterly buys, and annual contracts. Value added services include inventory management, rapid prototyping, process development, design for manufacturability, inspection, supply chain management, transportation, and logistics. Industries served include aerospace, automotive, defense, electronic, electrical, entertainment, food and beverage, health, industrial automation, machinery, medical, oil, energy, power, sporting goods, telecommunications, transportation, and more.

using high quality materials

for your sheet metal parts orders

We uses a wide range of material selections for our sheet metal fabrication process. Among our materials are aluminum, stainless steel, brass, magnesium, copper, carbon steel, bronze, galvanized steel, and more. Each material is available in different grades and varieties. Rest assured that all the materials used for your sheet metal parts are durable, corrosion-resistant, long-lasting, rust-proof, wear-resistant, and high-performance. If you want a specific material to be used in the sheet metal fabrication process, don’t hesitate to contact us!

- Carbon Steel

- Stainless Steel

- Aluminum

- Brass

- Copper

- Magnesium

- Bronze

- Galvanized Steel

Why BE-CU is Trusted by 1000+ Clients

Our sheet metal fabrication covers a lot of benefits to many industries, businesses, or projects. Below are the advantages of our services.

- Affordable and Fast Production:We can quickly produce different sheet metal prototypes and final products. KDM offers speedy production while assuring high precision. Our high-volume production also allows us to have cost-effect sheet metal fabrication services.

- Excellent Strength to Weight Ratio:Through our advanced sheet metal fabrication, we can produce sheet metal parts that are lightweight yet durable. We assure high strength, scratch resistance, and corrosion resistance to all produced sheet metal products.

- Wide Range of Materials and Techniques Used:We are experts in different sheet metal fabrication techniques that allow us to produce complex parts with additional intricate features such as notches, slots, holes, etc. Our wide range of sheet metal materials can also withstand electrical, high heat, corrosion, and more.

Online Contact China Precision Sheet Metal Manufacturers

As a direct supplier of precision machined and finished complete components to all segments of the aerospace, semiconductor, automotive, and medical industries, including innovative high tech startups, BE-CU Sheet metal manufacturer is your trusted source for precision sheet metal fabrication services.

To learn more about our aluminum,stainless steel and other steel alloy sheet metal fabrication services, contact us, or give us a call at +86 153 8731 8440, and one of our expert associates will assist you. BE-CU is your trusted source for premium sheet metal fabrication services and metal spinning china manufacturer.