Selecting the right metal fabrication firm is a critical decision for businesses and individuals seeking customized metal products. Whether you need components for industrial machinery, architectural elements, or decorative items, the quality and reliability of your chosen metal fabricator can significantly impact the outcome. This quick guide will help you navigate the process and make an informed decision when choosing a competent metal fabrication firm.

Define Your Requirements

Before you start your search, clearly define your project’s requirements. Understand the type of metal, design, and specifications needed. Having a comprehensive plan will enable you to convey your expectations effectively to potential fabricators.

Research and Referrals

Begin your search by researching local metal fabrication firms. Ask for recommendations from peers or industry contacts who have had positive experiences. Online reviews and business directories can also provide valuable insights into a company’s reputation and capabilities.

Evaluate Experience and Expertise

Assess the experience and expertise of the metal fabrication firm. Look for a company with a proven track record in projects similar to yours. A firm with a history of successfully handling diverse projects is more likely to meet your expectations.

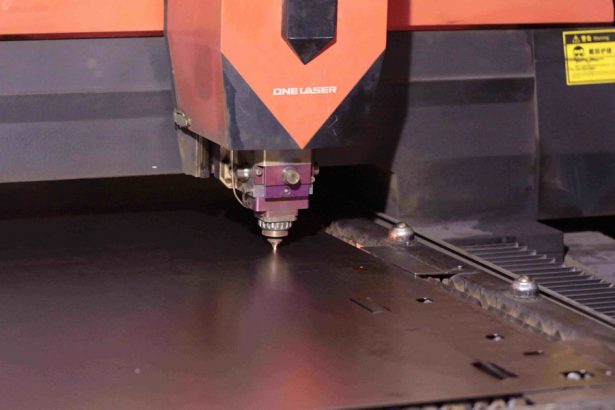

Facility and Equipment

Visit the fabricator’s facility if possible. A well-equipped and organized workspace indicates professionalism and efficiency. State-of-the-art equipment and technology are essential for precision and quality in metal fabrication.

Quality Control and Certification

Ensure the firm has a robust quality control process in place. Check if they are certified by relevant industry bodies. Certifications such as ISO, AWS, or ASME demonstrate a commitment to high standards and best practices.

Material Sourcing

Inquire about their sources for materials. The use of high-quality raw materials is crucial for the durability and performance of your metal products. Reputable fabricators have established relationships with reliable suppliers.

Customization and Design Capabilities

Assess the firm’s ability to accommodate custom designs and specifications. Skilled fabricators should have the capability to turn your vision into reality while offering suggestions for improvement.

Project Management and Timeline

Discuss project management and timelines. A competent metal fabricator should provide a clear project schedule and maintain effective communication throughout the process.

Pricing and Budget

Get multiple quotes from different fabricators, but be wary of overly low offers, as they may compromise quality. Compare pricing with the quality of work and the overall value offered.

References and Portfolio

Request references from previous clients and review the fabricator’s portfolio. Satisfied customers and a diverse portfolio are indicators of a reputable metal fabrication firm.

Communication and Collaboration

Open and transparent communication is essential throughout the project. Choose a fabricator that is willing to collaborate, address concerns, and provide regular updates on the progress of your project.

Warranty and After-Sales Support

Inquire about the warranty and after-sales support. A reliable fabricator stands by their work and offers assistance if issues arise after project completion.

Conclusion

Choosing a competent metal fabrication firm requires careful consideration of various factors, including experience, equipment, quality control, and communication. By following this quick guide, you can make an informed decision that ensures your metal fabrication project is a success, meeting or even exceeding your expectations. Remember that investing time in choosing the right fabricator can save you time, money, and potential headaches in the long run.

China Sheet Metal Fabrication Manufacturer

Custom precision metal fabrication services. Product specialties include UL® certified NEMA enclosures for various environmental conditions. Capabilities include punching, shearing, laser cutting, bending, machining, press brake forming, and welding. Materials worked with include mild steel, stainless steel, aluminum, brass, and more. Production volumes range from prototype to 10,000 pieces annually. Contract options include discrete orders, blanket orders, quarterly buys, and annual contracts. Value added services include inventory management, rapid prototyping, process development, design for manufacturability, inspection, supply chain management, transportation, and logistics. Industries served include aerospace, automotive, defense, electronic, electrical, entertainment, food and beverage, health, industrial automation, machinery, medical, oil, energy, power, sporting goods, telecommunications, transportation, and more.

using high quality materials

for your sheet metal parts orders

We uses a wide range of material selections for our sheet metal fabrication process. Among our materials are aluminum, stainless steel, brass, magnesium, copper, carbon steel, bronze, galvanized steel, and more. Each material is available in different grades and varieties. Rest assured that all the materials used for your sheet metal parts are durable, corrosion-resistant, long-lasting, rust-proof, wear-resistant, and high-performance. If you want a specific material to be used in the sheet metal fabrication process, don’t hesitate to contact us!

- Carbon Steel

- Stainless Steel

- Aluminum

- Brass

- Copper

- Magnesium

- Bronze

- Galvanized Steel

Why BE-CU is Trusted by 1000+ Clients

Our sheet metal fabrication covers a lot of benefits to many industries, businesses, or projects. Below are the advantages of our services.

- Affordable and Fast Production:We can quickly produce different sheet metal prototypes and final products. KDM offers speedy production while assuring high precision. Our high-volume production also allows us to have cost-effect sheet metal fabrication services.

- Excellent Strength to Weight Ratio:Through our advanced sheet metal fabrication, we can produce sheet metal parts that are lightweight yet durable. We assure high strength, scratch resistance, and corrosion resistance to all produced sheet metal products.

- Wide Range of Materials and Techniques Used:We are experts in different sheet metal fabrication techniques that allow us to produce complex parts with additional intricate features such as notches, slots, holes, etc. Our wide range of sheet metal materials can also withstand electrical, high heat, corrosion, and more.

Online Contact China Precision Sheet Metal Manufacturers

As a direct supplier of precision machined and finished complete components to all segments of the aerospace, semiconductor, automotive, and medical industries, including innovative high tech startups, BE-CU Sheet metal manufacturer is your trusted source for precision sheet metal fabrication services.

To learn more about our aluminum,stainless steel and other steel alloy sheet metal fabrication services, contact us, or give us a call at +86 153 8731 8440, and one of our expert associates will assist you. BE-CU is your trusted source for premium sheet metal fabrication services and metal spinning china manufacturer.