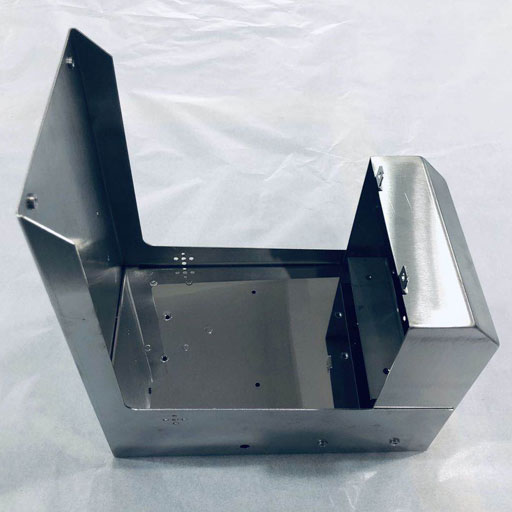

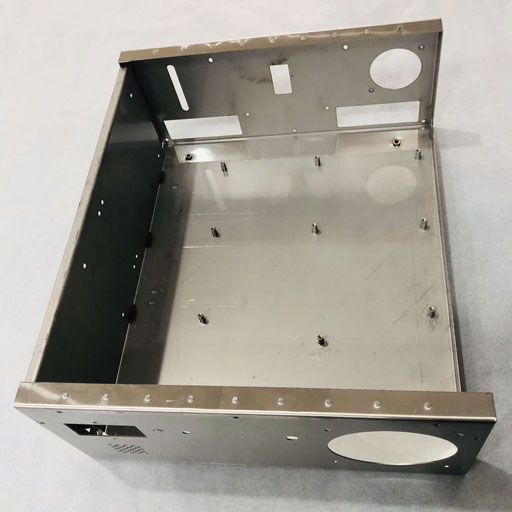

Custom Aluminum Sheet Metal Fabrication

We can heat-treat components to optimize the physical properties based on the application. We utilize cutting-edge laser cutting and cnc bending equipment, including 2000mm line layer laser cutting, and a wide range of advanced technology software to create custom components based on your specific requirements.

As an industry AS9100 and ISO9001:2015 certified metal working shop, we can ensure you will receive the high-performance aluminum sheet metal components you want with the mission-critical configurations you need.

Contact a Be-Cu sheet metal fabrication expert or submit an RFQ online and let us start cut and bending aluminum to your specifications.

| Processes | Laser Cutting/CNC Bending/Welding etc |

| Lead Time | As fast as 7 days |

| Finishing Options | Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating, Vibratory Tumbling |

| Tolerance | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

| Applications | Industrial applications, fittings, fasteners, cookware, medical devices |

| Alloys | 6061-T6, 7075-T6, 7050, 2024, 5052, 6063, etc |

Having developed a deep understanding of the key issues and dynamics that govern multiple industries and functional expertise, we are able to provide strategic advice to our clients helping them to acquire substantive business results of both a financial and operational nature.

Benefits of Fabrication Aluminum

Sheet metal fabrication using aluminum offers several benefits due to the unique properties of this material. Here are some key benefits of using aluminum for sheet metal fabrication:

- Lightweight: Aluminum is a lightweight material, making it ideal for applications where weight reduction is critical, such as in the aerospace and automotive industries. Its low density makes it easier to handle and transport.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer when exposed to air, which makes it highly resistant to corrosion. This property ensures that aluminum components have a long lifespan, even in harsh environments.

- High Strength-to-Weight Ratio: Aluminum alloys can offer excellent strength-to-weight ratios. This makes them suitable for applications where strength and durability are important without adding excessive weight, such as in the construction of aircraft and vehicles.

- Good Conductivity: Aluminum is an excellent conductor of electricity. This property is essential in electrical transmission lines, wiring, and various electrical applications.

- Thermal Conductivity: Aluminum has good thermal conductivity, making it useful in heat transfer applications. It is commonly used in heat sinks for electronic devices and in radiators for cooling systems.

- Ductility and Formability: Aluminum can be easily formed and shaped through various fabrication processes, such as rolling, extrusion, and forging. This property allows for the creation of complex and intricate designs.

- Recyclability: Aluminum is highly recyclable without a significant loss of quality or properties. Recycling aluminum requires only a fraction of the energy needed to produce it from raw materials, making it an environmentally friendly choice.

- Non-Toxic: Aluminum is non-toxic and does not release harmful fumes or substances when exposed to heat or in contact with food. This makes it suitable for a wide range of applications, including food packaging and cookware.

- Aesthetic Appeal: Aluminum’s sleek and modern appearance makes it a popular choice for architectural and design purposes. Its ability to be anodized or coated in various colors adds to its aesthetic versatility.

- Low Maintenance: Aluminum products typically require minimal maintenance due to their resistance to corrosion and durability. This reduces long-term costs and makes aluminum a cost-effective choice over time.

- Versatility: Aluminum can be alloyed with other metals to create a wide range of specialized alloys with varying properties, allowing it to meet specific requirements for different applications.

- Environmental Benefits: Aluminum’s light weight reduces fuel consumption in transportation applications, leading to lower carbon emissions. Its recyclability further contributes to its environmental sustainability.

These benefits make aluminum a popular choice for sheet metal fabrication in numerous industries, including automotive, aerospace, construction, food processing, pharmaceuticals, and more. When considering sheet metal fabrication projects, it’s important to assess the specific requirements and select the appropriate grade and finish of aluminum to optimize the desired properties for the intended application.

Case Studies

Aluminum Sheet Metal Manufacturing & Capabilities

Our precision sheet metal fabriction capabilities include in-house, full-service manufacturing for all Aluminum components. Our state-of-the-art metal working equipment and technology include:

- 7-axis (3D) and flat (2D) CNC Laser Cutter: Tolerance ranges from +/-0.001 in. to +/-0.005 in.Capable of handling sheets and plates with 16 gauge to 1.25 in. thickness, 20 to 90 ft. length and 7 to 12 ft. width.7 axis tube laser services available for up to 6 inch square and round tube.

- CNC Bending Machine : Bending plate up to 12 ft. width with 3/8 in. thickness. Bending tube parts from 1 1/2 to 3 1/2 in. sizes.

- Welding Machine: Welding assemblies with up to 24 ft. length and 92 in. dia.

- Quality Control: Temperature controlled inspection room with CMM and manual inspection capabilities.

- Software: Full 5-axis CAM system with machine simulation. We use Hypermill, Solidworks, MasterCAM, PC-DMIS CAD++ and Shoptech E2 Shop Management software.

Common Used Aluminum Grades Of Sheet Metal Fabrication

Sheet metal fabrication involves working with various aluminum alloys, each of which has specific properties suited to different applications. Some common aluminum grades used in sheet metal fabrication include:

- Aluminum 1100: This grade is known for its excellent formability and high corrosion resistance. It’s often used for general sheet metal work, including chemical and food processing equipment, as well as decorative applications.

- Aluminum 3003: Aluminum 3003 is another alloy with good formability and moderate strength. It’s commonly used in applications such as cooking utensils, roofing, and heat exchangers.

- Aluminum 5052: This alloy offers good corrosion resistance, strength, and weldability. It’s frequently used in marine and automotive components, as well as architectural and general sheet metal applications.

- Aluminum 6061: Known for its excellent weldability, 6061 aluminum is a versatile alloy with good strength and corrosion resistance. It’s used in a wide range of applications, including structural components, aerospace parts, and marine hardware.

- Aluminum 6063: This alloy is prized for its exceptional extrudability, making it ideal for complex shapes and designs. It’s commonly used in architectural and automotive applications, such as window frames and trim.

- Aluminum 7075: One of the strongest aluminum alloys available, 7075 offers excellent strength-to-weight ratio. It’s used in applications requiring high strength, such as aerospace components, bicycle frames, and rock climbing equipment.

- Aluminum 2024: This alloy is known for its high strength and fatigue resistance. It’s widely used in aerospace and aircraft applications, such as aircraft skins, rivets, and structural components.

- Aluminum 5083: 5083 is a marine-grade aluminum alloy with excellent corrosion resistance. It’s frequently used for boat hulls, pressure vessels, and other marine and underwater applications.

- Aluminum 2014: This alloy offers good machinability and high strength. It’s commonly used in aerospace and structural applications, such as aircraft fittings and gears.

- Aluminum 3004: This alloy combines good formability with moderate strength and corrosion resistance. It’s often used in the manufacture of beverage cans, roofing, and building panels.

The choice of aluminum grade for sheet metal fabrication depends on the specific requirements of the project, including factors like strength, corrosion resistance, formability, and cost. It’s important to select the right grade to ensure the final product meets its intended purpose effectively.

Work with Aluminum Sheet Metal Fabrication Experts

Years of aluminum sheet metal fabrication experience have provided Be-Cu with the expertise needed for high-performance aluminum fabrication parts. Email us at [email protected] or contact us to start your aluminum project.