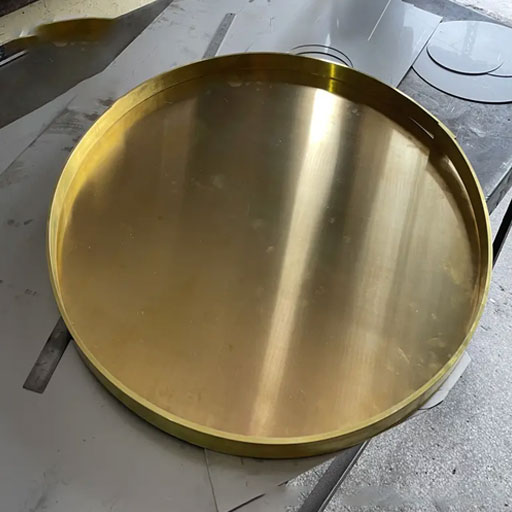

Custom Brass Sheet Metal Fabrication

Brass, an alloy of copper and zinc, is a very popular material for sheet metal. With its excellent dimensional accuracy, robustness, durability and corrosion resistance, there is a high demand for copper sheet metal fabrication products. We manufacture a wide range of brass sheet metal parts, including knobs, hinges, nuts and bolts, gears, handles, and other hardware and decorative pieces. We are equipped with state-of-the-art laser cutter and precision cnc bending facilities, which enable us to fabrication precision brass parts with tight tolerances and surface finishes to customer specifications. In addition, the parts are hard heat treated and chemically plated according to the functional characteristics of the customer’s products to improve mechanical properties and wear resistance for maximum performance.

At Be-Cu, our highly skilled workers can offer our customers the custom brass fabrication they need while also providing them with the best cost-cutting designs to get the job done correctly and as efficiently as possible every time.

Only need to submit 2D and 3D CAD drawings, and then we can provide a custom machined parts design for manufacturing review upon receiving your order, and will send the quotation to you in 1 day. If the quote is delayed, we will notify you as soon as possible.Precision sheet metal fabrication services, welcome to contact us.

| Processes | Laser Cutting/CNC Bending/Welding etc |

| Lead Time | As fast as 7 days |

| Finishing Options | Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating, Vibratory Tumbling |

| Tolerance | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

| Applications | Knobs, hinges, nuts and bolts, gears, handles, and other hardware and decorative pieces |

| Alloys | Brass Alloy |

Having developed a deep understanding of the key issues and dynamics that govern multiple industries and functional expertise, we are able to provide strategic advice to our clients helping them to acquire substantive business results of both a financial and operational nature.

Benefits of Fabrication Brass

Sheet metal fabrication using brass offers several benefits due to the unique properties of brass as a material. Brass is an alloy primarily composed of copper and zinc, and it is known for its durability, corrosion resistance, and attractive appearance. Here are some of the benefits of using brass in sheet metal fabrication:

- Corrosion Resistance: Brass has excellent corrosion resistance, making it suitable for a wide range of applications, including outdoor and marine environments. It does not rust or corrode easily, which extends the lifespan of fabricated components.

- Durability: Brass is a durable material that can withstand wear and tear, making it suitable for applications where strength and longevity are essential. It is particularly well-suited for parts that require high-stress resistance.

- Aesthetic Appeal: Brass has a distinctive gold-like appearance that adds an attractive aesthetic element to fabricated products. It is often used for decorative purposes in architecture, jewelry, and interior design.

- Malleability and Formability: Brass is a malleable material, meaning it can be easily shaped, bent, and formed into complex geometries during the sheet metal fabrication process. This versatility allows for the creation of intricate and custom designs.

- Good Heat and Electrical Conductivity: Brass has excellent heat and electrical conductivity, making it suitable for applications that require efficient heat transfer or electrical conductivity, such as heat exchangers and electrical connectors.

- Machinability: Brass is easy to machine, which simplifies the fabrication process and reduces production time and costs. It can be drilled, milled, turned, and threaded with relative ease.

- Low Friction Coefficient: Brass has a low coefficient of friction, making it an excellent choice for components that require smooth and low-friction movement, such as bearings and gears.

- Recyclability: Brass is a recyclable material, which is beneficial for sustainability and reducing environmental impact. Recycling brass is energy-efficient and helps conserve natural resources.

- Non-Magnetic: Brass is a non-magnetic material, making it suitable for applications where magnetism could interfere with the operation of components or equipment.

- Biocompatibility: Brass is biocompatible and has been used in medical applications, such as orthopedic implants and dental fixtures, where it is important to minimize the risk of allergic reactions or adverse tissue responses.

- Antimicrobial Properties: Some types of brass, such as antimicrobial brass alloys, have been developed with added antimicrobial properties. These alloys can help reduce the growth of bacteria and microbes on surfaces, making them suitable for hygiene-critical applications.

- Cost-Effective: Brass is often a cost-effective choice for sheet metal fabrication, especially when compared to other materials with similar properties, such as bronze or stainless steel.

Overall, the benefits of using brass in sheet metal fabrication make it a versatile and attractive option for various industries and applications, ranging from architectural design to aerospace engineering.

Case Studies

Brass Sheet Metal Manufacturing & Capabilities

Our precision sheet metal fabriction capabilities include in-house, full-service manufacturing for all brass components. Our state-of-the-art metal working equipment and technology include:

- 7-axis (3D) and flat (2D) CNC Laser Cutter: Tolerance ranges from +/-0.001 in. to +/-0.005 in.Capable of handling sheets and plates with 16 gauge to 1.25 in. thickness, 20 to 90 ft. length and 7 to 12 ft. width.7 axis tube laser services available for up to 6 inch square and round tube.

- CNC Bending Machine : Bending plate up to 12 ft. width with 3/8 in. thickness. Bending tube parts from 1 1/2 to 3 1/2 in. sizes.

- Welding Machine: Welding assemblies with up to 24 ft. length and 92 in. dia.

- Quality Control: Temperature controlled inspection room with CMM and manual inspection capabilities.

- Software: Full 5-axis CAM system with machine simulation. We use Hypermill, Solidworks, MasterCAM, PC-DMIS CAD++ and Shoptech E2 Shop Management software.

Common Used Brass Grades Of Sheet Metal Fabrication

Brass is a popular material for sheet metal fabrication due to its corrosion resistance, malleability, and attractive appearance. There are several common brass grades used in sheet metal fabrication, each with its own unique properties and applications. Some of the most commonly used brass grades in sheet metal fabrication include:

- C26000 (Cartridge Brass):

- Alloyed with zinc and sometimes small amounts of other elements.

- Offers good strength, ductility, and cold workability.

- Often used for sheet metal fabrication, ammunition casings, and musical instruments.

- C27000 (Yellow Brass):

- Contains a higher percentage of copper compared to C26000, which makes it slightly more corrosion-resistant.

- Offers good formability and solderability.

- Commonly used in architectural applications, plumbing fixtures, and decorative components.

- C28000 (Muntz Metal):

- A higher zinc content gives it improved strength and wear resistance.

- Often used in marine applications, such as boat hulls and propellers, due to its resistance to seawater corrosion.

- C35300 (High Leaded Brass):

- Contains a higher lead content, which improves machinability.

- Suitable for applications where machining is required, such as fittings and connectors.

- C46400 (Naval Brass):

- Contains a higher percentage of tin, which enhances corrosion resistance in marine environments.

- Used in marine and naval applications, such as shipbuilding and propellers.

- C48500 (Leaded Muntz Metal):

- Similar to C28000 but with added lead for improved machinability.

- Commonly used in marine and architectural applications.

- C68700 (Aluminum Brass):

- Contains aluminum and is known for its excellent corrosion resistance in seawater.

- Used in heat exchangers and condensers for marine and industrial applications.

- C2600 (Brass Alloy 70/30):

- Contains 70% copper and 30% zinc.

- Offers good electrical conductivity and is used in electrical connectors and terminals.

- C22000 (Commercial Bronze):

- Not strictly brass, but often categorized with brass alloys.

- Contains copper and tin, offering good formability and corrosion resistance.

- Used for sheet metal applications where corrosion resistance and an attractive appearance are essential.

When selecting a brass grade for sheet metal fabrication, consider factors such as the specific application, desired mechanical properties, corrosion resistance requirements, and cost constraints. Each brass alloy has its own set of characteristics, and the choice should align with the intended use of the fabricated parts.

Work with Brass Sheet Metal Fabrication Experts

Years of Brass sheet metal fabrication experience have provided Be-Cu with the expertise needed for high-performance Brass fabrication parts. Email us at [email protected] or contact us to start your Brass project.