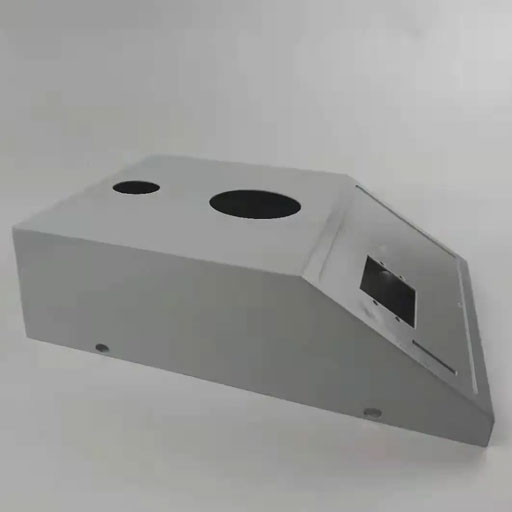

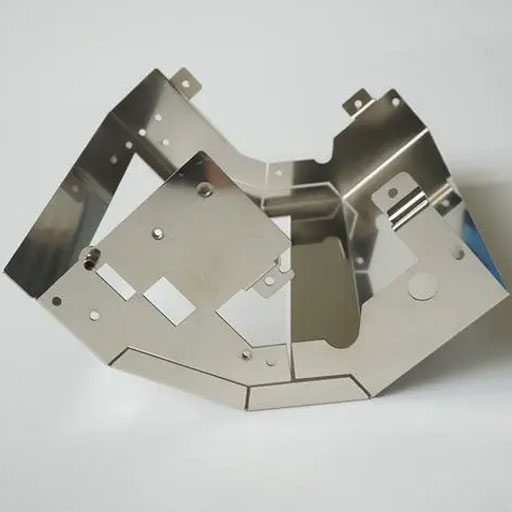

Custom Stainless Steel Sheet Metal Fabrication

We can heat-treat components to optimize the physical properties based on the application. We utilize cutting-edge laser cutting and cnc bending equipment, including 2000mm line layer laser cutting, and a wide range of advanced technology software to create custom components based on your specific requirements.

As an industry AS9100 and ISO9001:2015 certified metal working shop, we can ensure you will receive the high-performance stainless steel sheet metal components you want with the mission-critical configurations you need.

Contact a Be-Cu sheet metal fabrication expert or submit an RFQ online and let us start cut and bending stainless steel to your specifications.

| Processes | Laser Cutting/CNC Bending/Welding etc |

| Lead Time | As fast as 7 days |

| Finishing Options | Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating, Vibratory Tumbling |

| Tolerance | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

| Applications | Industrial applications, fittings, fasteners, cookware, medical devices |

| Alloys | 303, 304L, 316L, 410, 416, 440C, 17-4PH, Nitronic 60 |

Having developed a deep understanding of the key issues and dynamics that govern multiple industries and functional expertise, we are able to provide strategic advice to our clients helping them to acquire substantive business results of both a financial and operational nature.

Benefits of Fabrication Stainless Steel

Sheet metal fabrication using stainless steel offers several benefits due to the unique properties of this material. Here are some key benefits of using stainless steel for sheet metal fabrication:

- Corrosion Resistance: Stainless steel is highly resistant to corrosion and rust, making it suitable for a wide range of applications, including outdoor and harsh environments. It maintains its appearance and integrity over time, reducing maintenance and replacement costs.

- Strength and Durability: Stainless steel is known for its strength and durability. It provides excellent structural integrity and can withstand heavy loads and high temperatures, making it suitable for demanding applications.

- Aesthetic Appeal: Stainless steel has a clean and modern appearance that is aesthetically appealing. It is often used in architectural and decorative applications where visual appeal is important.

- Hygienic Properties: Stainless steel has hygienic properties, making it ideal for applications in the food and beverage industry, medical equipment, and sanitary environments. It is easy to clean and resistant to bacterial growth.

- Heat and Fire Resistance: Stainless steel has excellent heat resistance properties, making it suitable for applications that involve high temperatures. It retains its strength and structural integrity even at elevated temperatures. Additionally, stainless steel has a high melting point, providing fire resistance.

- Weldability and Formability: Stainless steel is highly weldable and formable, allowing for various fabrication techniques such as welding, bending, and shaping. This versatility enables the creation of complex shapes and designs.

- Recyclability: Stainless steel is a sustainable material as it is 100% recyclable. It can be recycled repeatedly without losing its properties, reducing the environmental impact and promoting a circular economy.

- Chemical Resistance: Stainless steel exhibits excellent resistance to a wide range of chemicals, acids, and solvents, making it suitable for applications where chemical exposure is a concern.

- Longevity: Stainless steel has a long lifespan due to its durability and resistance to corrosion, wear, and tear. It provides a cost-effective solution as it requires less maintenance and replacement over time.

- Compatibility: Stainless steel is compatible with other materials, allowing for integration with different components or structures in various applications.

These benefits make stainless steel a popular choice for sheet metal fabrication in numerous industries, including automotive, aerospace, construction, food processing, pharmaceuticals, and more. When considering sheet metal fabrication projects, it’s important to assess the specific requirements and select the appropriate grade and finish of stainless steel to optimize the desired properties for the intended application.

Case Studies

Stainless Steel Sheet Metal Manufacturing & Capabilities

Our precision sheet metal fabriction capabilities include in-house, full-service manufacturing for all stainless steel components. Our state-of-the-art metal working equipment and technology include:

- 7-axis (3D) and flat (2D) CNC Laser Cutter: Tolerance ranges from +/-0.001 in. to +/-0.005 in.Capable of handling sheets and plates with 16 gauge to 1.25 in. thickness, 20 to 90 ft. length and 7 to 12 ft. width.7 axis tube laser services available for up to 6 inch square and round tube.

- CNC Bending Machine : Bending plate up to 12 ft. width with 3/8 in. thickness. Bending tube parts from 1 1/2 to 3 1/2 in. sizes.

- Welding Machine: Welding assemblies with up to 24 ft. length and 92 in. dia.

- Quality Control: Temperature controlled inspection room with CMM and manual inspection capabilities.

- Software: Full 5-axis CAM system with machine simulation. We use Hypermill, Solidworks, MasterCAM, PC-DMIS CAD++ and Shoptech E2 Shop Management software.

Common Used Stainless Steel Grades Of Sheet Metal Fabrication

Stainless steel is classified into different grades based on their chemical composition and properties. The two most common stainless steel grades used in sheet metal fabrication are from the 300 series and the 400 series. Additionally, there are other specialty grades used for specific applications. Here’s an overview of these stainless steel grades:

300 Series Stainless Steel:

- 304 Stainless Steel: This is the most widely used stainless steel grade, known for its excellent corrosion resistance, formability, and weldability. It is commonly used in general sheet metal fabrication, food processing equipment, architectural applications, and kitchen appliances.

- 316 Stainless Steel: This grade offers even higher corrosion resistance than 304 stainless steel, particularly against pitting and chloride environments. It is commonly used in marine applications, chemical processing equipment, and medical devices.

400 Series Stainless Steel:

- 430 Stainless Steel: This grade is known for its good corrosion resistance and formability. It is often used in decorative applications, automotive trim, and appliances.

- 410 Stainless Steel: It is a heat-treatable martensitic stainless steel with good corrosion resistance, strength, and hardness. It finds applications in cutlery, industrial equipment, and pump shafts.

Additional Grades:

- 316L Stainless Steel: This is a low carbon version of 316 stainless steel, offering improved weldability and resistance to sensitization. It is commonly used in applications where welding is required.

- 17-4 PH Stainless Steel: It is a precipitation-hardening stainless steel known for its high strength and corrosion resistance. It is used in aerospace components, nuclear waste casks, and various industrial applications.

- 301 Stainless Steel: This grade has high strength and good ductility. It is often used for springs, washers, brackets, and other components requiring high tensile strength.

It’s important to choose the appropriate stainless steel grade based on the specific requirements of the sheet metal fabrication project, including factors such as corrosion resistance, strength, formability, and aesthetics. Additionally, there are specialized stainless steel grades available for specific applications, such as duplex stainless steels for high-strength and corrosion-resistant applications or super austenitic stainless steels for extreme corrosive environments. Consulting with Be-Cu sheet metal fabrication expert can help in selecting the most suitable grade for your specific sheet metal fabrication needs.

Work with Stainless Steel Sheet Metal Fabrication Experts

Years of stainless steel sheet metal fabrication experience have provided Be-Cu with the expertise needed for high-performance stainless steel machined parts. Email us at [email protected] or contact us to start your stainless steel project.