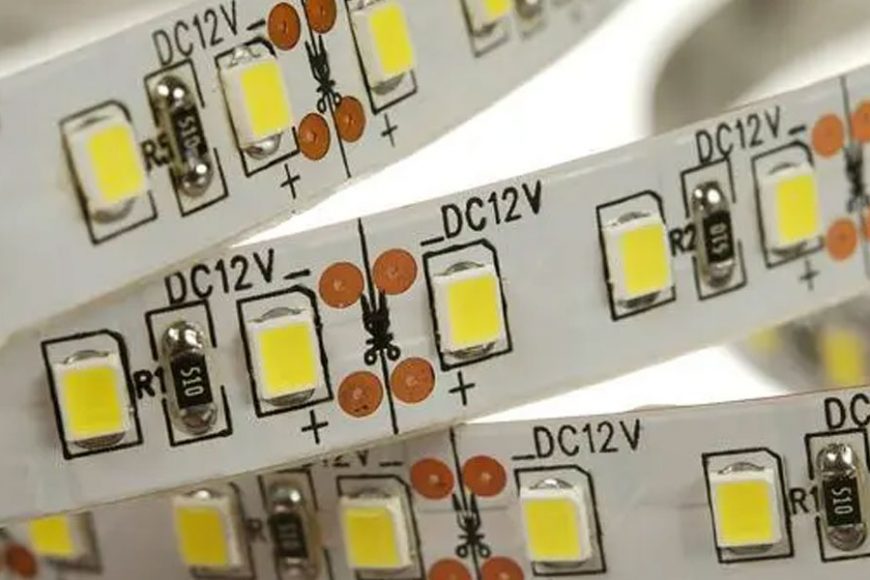

As an efficient and energy-saving light source, LED (Light Emitting Diode) has been widely used in various fields, from indoor lighting to electronic display, and even automotive lighting. The packaging technology of LED is one of the important guarantees of its performance and stability, and in LED packaging, glass etching technology plays a vital role.

LED packaging glass etching is a technology that uses chemicals to etch the LED glass shell. Its purpose is to improve the photoelectric performance of LEDs, improve their brightness and luminous efficiency through etching during the LED packaging process. As one of the pioneers in the field of LED packaging, BE-CU Technology Co., Ltd. is committed to the research and development and promotion of key LED packaging technologies, including glass etching technology, which provides important support for the development and innovation of the LED industry.

First of all, the key role of LED packaging glass etching process is to optimize the photoelectric conversion efficiency of LEDs. The luminous efficiency of LEDs is affected by many factors, one of which is the refractive index mismatch of LED packaging materials. In the LED packaging process, LED chips need to be encapsulated in transparent materials to protect the chips and export light. One of the commonly used packaging materials is glass, but the refractive index of ordinary glass does not match the refractive index of the LED chip, which will cause part of the light to be reflected on the surface of the packaging material and unable to be output, reducing the luminous efficiency of the LED. BE-CU Technology Co., Ltd.’s LED packaging glass etching technology can adjust the refractive index of the glass through etching treatment, making it closer to the refractive index of the LED chip, reducing the reflection loss of light, and thus improving the luminous efficiency of the LED.

Secondly, LED packaging glass etching technology can also improve the luminous uniformity and color temperature consistency of the LED. In the LED packaging process, due to the unevenness of the glass surface or the difference in glass materials, the luminous uniformity and color temperature of the LED will be inconsistent, affecting the overall photoelectric performance of the LED. BE-CU Metal Etching Company. can adjust the morphology and structure of the glass surface through precise etching control through LED packaging glass etching technology, making it more flat and uniform, thereby improving the luminous uniformity and color temperature consistency of the LED.

In addition, LED packaging glass etching technology can also enhance the weather resistance and corrosion resistance of LEDs. As a commonly used light source, LEDs often need to be used in various harsh environments, such as outdoor lighting, automotive lighting, etc. Ordinary packaging materials often cannot resist external erosion and damage well, resulting in a short service life of LEDs. BE-CU Metal Etching Company.’s LED packaging glass etching technology can change the chemical properties of the glass surface, enhance its weather resistance and corrosion resistance, so that LEDs can maintain stable performance and long service life in harsh environments.

In summary, LED packaging glass etching technology is one of the key technologies to achieve efficient photoelectric conversion. BE-CU Metal Etching Company is committed to promoting the development and innovation of LED packaging technology, and contributes to the progress and development of the LED industry by optimizing the photoelectric performance of LEDs, improving the uniformity of luminescence and the consistency of color temperature, and enhancing the weather resistance and corrosion resistance of LEDs.

China Sheet Metal Fabrication Manufacturer

Custom precision metal fabrication services. Product specialties include UL® certified NEMA enclosures for various environmental conditions. Capabilities include punching, shearing, laser cutting, bending, machining, press brake forming, and welding. Materials worked with include mild steel, stainless steel, aluminum, brass, and more. Production volumes range from prototype to 10,000 pieces annually. Contract options include discrete orders, blanket orders, quarterly buys, and annual contracts. Value added services include inventory management, rapid prototyping, process development, design for manufacturability, inspection, supply chain management, transportation, and logistics. Industries served include aerospace, automotive, defense, electronic, electrical, entertainment, food and beverage, health, industrial automation, machinery, medical, oil, energy, power, sporting goods, telecommunications, transportation, and more.

using high quality materials

for your sheet metal parts orders

We uses a wide range of material selections for our sheet metal fabrication process. Among our materials are aluminum, stainless steel, brass, magnesium, copper, carbon steel, bronze, galvanized steel, and more. Each material is available in different grades and varieties. Rest assured that all the materials used for your sheet metal parts are durable, corrosion-resistant, long-lasting, rust-proof, wear-resistant, and high-performance. If you want a specific material to be used in the sheet metal fabrication process, don’t hesitate to contact us!

- Carbon Steel

- Stainless Steel

- Aluminum

- Brass

- Copper

- Magnesium

- Bronze

- Galvanized Steel

Why BE-CU is Trusted by 1000+ Clients

Our sheet metal fabrication covers a lot of benefits to many industries, businesses, or projects. Below are the advantages of our services.

- Affordable and Fast Production:We can quickly produce different sheet metal prototypes and final products. KDM offers speedy production while assuring high precision. Our high-volume production also allows us to have cost-effect sheet metal fabrication services.

- Excellent Strength to Weight Ratio:Through our advanced sheet metal fabrication, we can produce sheet metal parts that are lightweight yet durable. We assure high strength, scratch resistance, and corrosion resistance to all produced sheet metal products.

- Wide Range of Materials and Techniques Used:We are experts in different sheet metal fabrication techniques that allow us to produce complex parts with additional intricate features such as notches, slots, holes, etc. Our wide range of sheet metal materials can also withstand electrical, high heat, corrosion, and more.

Online Contact China Precision Sheet Metal Manufacturers

As a direct supplier of precision machined and finished complete components to all segments of the aerospace, semiconductor, automotive, and medical industries, including innovative high tech startups, BE-CU Sheet metal manufacturer is your trusted source for precision sheet metal fabrication services.

To learn more about our aluminum,stainless steel and other steel alloy sheet metal fabrication services, contact us, or give us a call at +86 153 8731 8440, and one of our expert associates will assist you. BE-CU is your trusted source for premium sheet metal fabrication services and metal spinning china manufacturer.