Metal fabrication is a precise and intricate process that demands accuracy and attention to detail. Whether you’re creating components for a construction project, manufacturing machinery, or crafting custom metalwork, achieving precise results is paramount. In this article, we will explore the best way to ensure precision in your metal fabrication projects. From the choice of materials to the cutting and welding techniques, we’ll cover the essential steps to help you achieve the finest quality results.

Material Selection

The foundation of any successful metal fabrication project is the selection of the right materials. To achieve precise results, you need to choose the appropriate metal type, thickness, and quality. Steel, aluminum, and stainless steel are common choices, each with its unique properties. Factors like corrosion resistance, strength, and weight can significantly impact the final product. Ensuring that the material is free from defects and impurities is crucial to prevent issues during fabrication.

Detailed Planning and Design

Before you begin cutting and welding, meticulous planning and design are essential. Start by creating comprehensive blueprints or CAD (Computer-Aided Design) models that outline every dimension and detail. Ensure that your measurements are accurate, and all tolerances are considered. Precision in planning will translate to precision in the final product.

Cutting Techniques

The cutting phase of metal fabrication is where precision plays a vital role. Laser cutting, water jet cutting, and plasma cutting are some of the methods used to shape metal. Laser cutting, in particular, offers exceptional precision, creating clean and sharp edges. The choice of cutting technique depends on the material, thickness, and intricacy of your design.

CNC Machining

Computer Numerical Control (CNC) machining is another indispensable tool for precise metal fabrication. CNC machines are programmed to execute highly accurate and repeatable operations. These machines can cut, drill, and shape metal with incredible precision, ensuring that each piece is identical to the next. This level of accuracy is particularly important in industries like aerospace and automotive manufacturing.

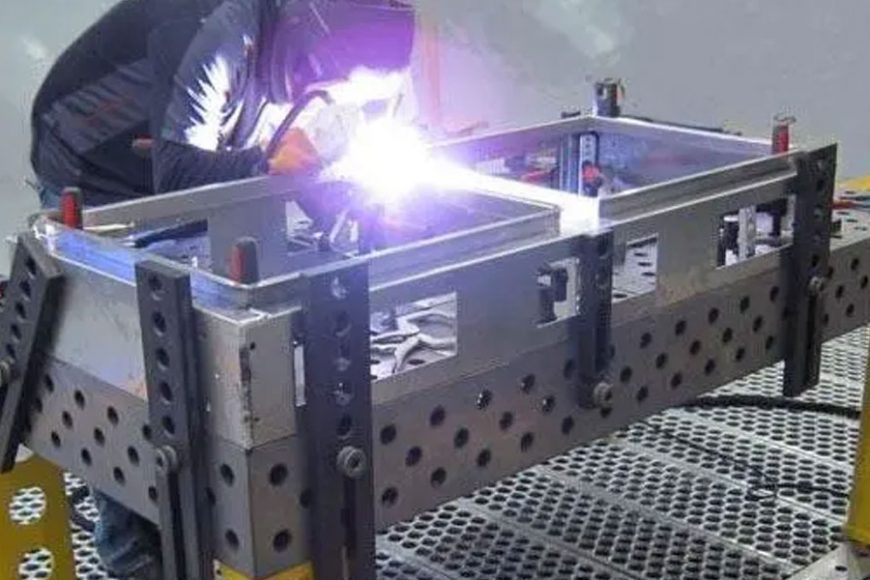

Welding Techniques

Welding is where various components come together to form the final product. Achieving precise welds is essential to ensure structural integrity and aesthetic appeal. MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding are two common methods known for their precision and control. Skilled welders can maintain tight tolerances, preventing warping and distortion while creating strong, reliable joints.

Quality Control

Quality control is an ongoing process throughout the fabrication project. Regular inspections, measurements, and tests should be conducted to ensure that the final product meets the specified tolerances and standards. This can include non-destructive testing methods like ultrasonic testing and magnetic particle inspection.

Skilled Workforce

An experienced and skilled workforce is a fundamental component of achieving precision in metal fabrication. Training and certification programs for welders and fabricators ensure that the individuals working on your project have the knowledge and expertise needed to meet your specifications. Investing in a highly trained team can significantly enhance the precision of your metal fabrication projects.

Conclusion

Metal fabrication is an art that demands precision at every step of the process. From material selection to welding techniques and quality control, attention to detail and accuracy are non-negotiable. Achieving precise results in your metal fabrication projects requires a combination of advanced technology, careful planning, and a skilled workforce. By following these guidelines, you can produce metal components and structures that meet the highest standards of quality and precision.

China Sheet Metal Fabrication Manufacturer

Custom precision metal fabrication services. Product specialties include UL® certified NEMA enclosures for various environmental conditions. Capabilities include punching, shearing, laser cutting, bending, machining, press brake forming, and welding. Materials worked with include mild steel, stainless steel, aluminum, brass, and more. Production volumes range from prototype to 10,000 pieces annually. Contract options include discrete orders, blanket orders, quarterly buys, and annual contracts. Value added services include inventory management, rapid prototyping, process development, design for manufacturability, inspection, supply chain management, transportation, and logistics. Industries served include aerospace, automotive, defense, electronic, electrical, entertainment, food and beverage, health, industrial automation, machinery, medical, oil, energy, power, sporting goods, telecommunications, transportation, and more.

using high quality materials

for your sheet metal parts orders

We uses a wide range of material selections for our sheet metal fabrication process. Among our materials are aluminum, stainless steel, brass, magnesium, copper, carbon steel, bronze, galvanized steel, and more. Each material is available in different grades and varieties. Rest assured that all the materials used for your sheet metal parts are durable, corrosion-resistant, long-lasting, rust-proof, wear-resistant, and high-performance. If you want a specific material to be used in the sheet metal fabrication process, don’t hesitate to contact us!

- Carbon Steel

- Stainless Steel

- Aluminum

- Brass

- Copper

- Magnesium

- Bronze

- Galvanized Steel

Why BE-CU is Trusted by 1000+ Clients

Our sheet metal fabrication covers a lot of benefits to many industries, businesses, or projects. Below are the advantages of our services.

- Affordable and Fast Production:We can quickly produce different sheet metal prototypes and final products. KDM offers speedy production while assuring high precision. Our high-volume production also allows us to have cost-effect sheet metal fabrication services.

- Excellent Strength to Weight Ratio:Through our advanced sheet metal fabrication, we can produce sheet metal parts that are lightweight yet durable. We assure high strength, scratch resistance, and corrosion resistance to all produced sheet metal products.

- Wide Range of Materials and Techniques Used:We are experts in different sheet metal fabrication techniques that allow us to produce complex parts with additional intricate features such as notches, slots, holes, etc. Our wide range of sheet metal materials can also withstand electrical, high heat, corrosion, and more.

Online Contact China Precision Sheet Metal Manufacturers

As a direct supplier of precision machined and finished complete components to all segments of the aerospace, semiconductor, automotive, and medical industries, including innovative high tech startups, BE-CU Sheet metal manufacturer is your trusted source for precision sheet metal fabrication services.

To learn more about our aluminum,stainless steel and other steel alloy sheet metal fabrication services, contact us, or give us a call at +86 153 8731 8440, and one of our expert associates will assist you. BE-CU is your trusted source for premium sheet metal fabrication services and metal spinning china manufacturer.