Metal laser cutting has revolutionized the manufacturing industry, offering precise and efficient methods for cutting metal sheets and components. While the benefits of laser cutting are undeniable, cost-efficiency remains a significant concern for businesses looking to optimize their operations. Fortunately, there are proven ways to reduce metal laser cutting costs without compromising quality or precision. In this article, we will explore some strategies that can help your company save money while still benefiting from the advantages of laser cutting technology.

Material Optimization

One of the most effective ways to reduce metal laser cutting costs is to optimize the use of materials. This involves minimizing waste by accurately planning and nesting the parts to be cut. Using computer-aided design (CAD) and computer-aided manufacturing (CAM) software, you can maximize the utilization of your metal sheets, thereby reducing the amount of scrap material and saving both money and resources.

Batch Processing

Batch processing is another technique that can help lower costs. Instead of cutting individual parts one by one, consider grouping similar components together for a single run. This reduces setup and changeover time, leading to increased productivity and cost savings.

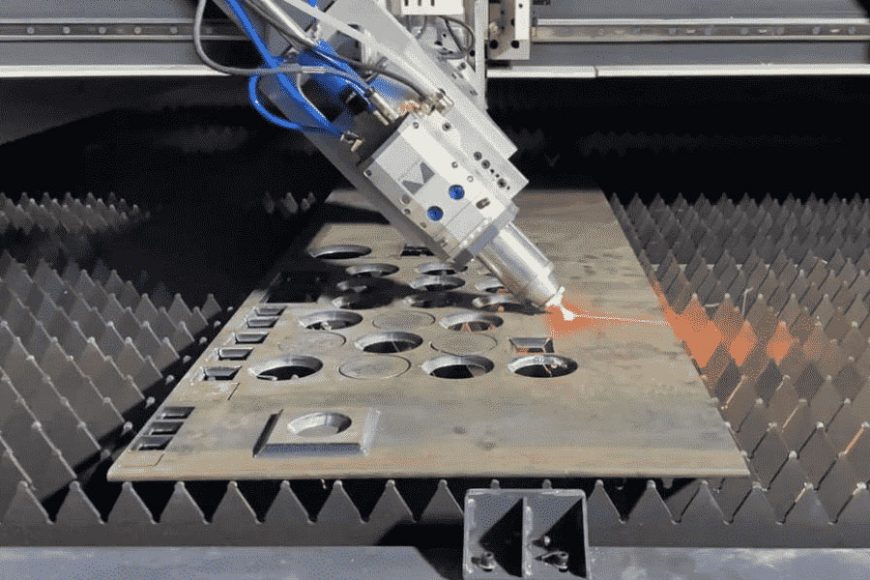

Advanced Cutting Technology

Investing in state-of-the-art laser cutting machines can be a wise long-term decision. Modern laser cutting equipment is not only more efficient but also consumes less energy. By upgrading your machinery, you can take advantage of improved cutting speeds, precision, and reduced operating costs.

Maintenance and Calibration

Regular maintenance and calibration of your laser cutting equipment are essential for ensuring its longevity and optimal performance. Well-maintained machines tend to consume less energy and produce less waste, resulting in cost savings over time.

Automation

Automation is a key component of cost reduction in laser cutting. Automated loading and unloading systems, as well as real-time monitoring and control, can significantly increase production efficiency and reduce labor costs. Implementing automation also enhances the overall safety of the cutting process.

Workpiece Design

The design of the workpieces themselves can impact laser cutting costs. Complex shapes and intricate details may require longer cutting times and more precise adjustments, increasing the overall cost. Simplifying the design of components, whenever possible, can lead to substantial savings.

Choose the Right Laser Source

Selecting the appropriate laser source for your specific cutting needs is crucial. CO2 and fiber lasers are two common options, each with its advantages and disadvantages. Fiber lasers are known for their energy efficiency, offering potential savings in operating costs.

Bulk Material Purchases

Buying metal sheets in bulk can lead to cost reductions through volume discounts. Carefully analyze your production needs and order materials accordingly to enjoy the financial benefits of bulk purchasing.

Vendor Negotiation

Laser cutting service providers may offer volume discounts and competitive pricing for long-term partnerships. Negotiating contracts and establishing reliable relationships with vendors can lead to more favorable pricing agreements, ultimately reducing your laser cutting costs.

Energy Efficiency

Implement energy-efficient practices, such as optimizing cutting parameters and reducing idle machine times. Simple adjustments like turning off equipment when not in use and using energy-saving modes can lower your energy bills.

Conclusion

Reducing metal laser cutting costs is achievable through a combination of smart practices and strategic investments. By optimizing material usage, batch processing, upgrading equipment, performing regular maintenance, and adopting automation, your business can save money while enjoying the benefits of precise and efficient metal cutting. Furthermore, paying attention to the design of workpieces, choosing the right laser source, buying materials in bulk, negotiating with vendors, and embracing energy-efficient practices can all contribute to significant cost reductions. Implementing these proven strategies will not only make your laser cutting processes more economical but also more sustainable in the long run.

China Sheet Metal Fabrication Manufacturer

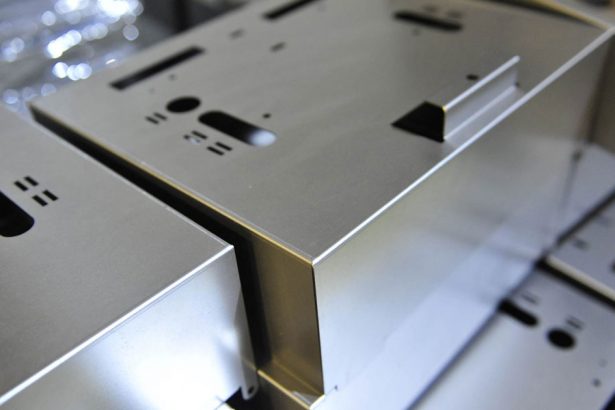

Custom precision metal fabrication services. Product specialties include UL® certified NEMA enclosures for various environmental conditions. Capabilities include punching, shearing, laser cutting, bending, machining, press brake forming, and welding. Materials worked with include mild steel, stainless steel, aluminum, brass, and more. Production volumes range from prototype to 10,000 pieces annually. Contract options include discrete orders, blanket orders, quarterly buys, and annual contracts. Value added services include inventory management, rapid prototyping, process development, design for manufacturability, inspection, supply chain management, transportation, and logistics. Industries served include aerospace, automotive, defense, electronic, electrical, entertainment, food and beverage, health, industrial automation, machinery, medical, oil, energy, power, sporting goods, telecommunications, transportation, and more.

using high quality materials

for your sheet metal parts orders

We uses a wide range of material selections for our sheet metal fabrication process. Among our materials are aluminum, stainless steel, brass, magnesium, copper, carbon steel, bronze, galvanized steel, and more. Each material is available in different grades and varieties. Rest assured that all the materials used for your sheet metal parts are durable, corrosion-resistant, long-lasting, rust-proof, wear-resistant, and high-performance. If you want a specific material to be used in the sheet metal fabrication process, don’t hesitate to contact us!

- Carbon Steel

- Stainless Steel

- Aluminum

- Brass

- Copper

- Magnesium

- Bronze

- Galvanized Steel

Why BE-CU is Trusted by 1000+ Clients

Our sheet metal fabrication covers a lot of benefits to many industries, businesses, or projects. Below are the advantages of our services.

- Affordable and Fast Production:We can quickly produce different sheet metal prototypes and final products. KDM offers speedy production while assuring high precision. Our high-volume production also allows us to have cost-effect sheet metal fabrication services.

- Excellent Strength to Weight Ratio:Through our advanced sheet metal fabrication, we can produce sheet metal parts that are lightweight yet durable. We assure high strength, scratch resistance, and corrosion resistance to all produced sheet metal products.

- Wide Range of Materials and Techniques Used:We are experts in different sheet metal fabrication techniques that allow us to produce complex parts with additional intricate features such as notches, slots, holes, etc. Our wide range of sheet metal materials can also withstand electrical, high heat, corrosion, and more.

Online Contact China Precision Sheet Metal Manufacturers

As a direct supplier of precision machined and finished complete components to all segments of the aerospace, semiconductor, automotive, and medical industries, including innovative high tech startups, BE-CU Sheet metal manufacturer is your trusted source for precision sheet metal fabrication services.

To learn more about our aluminum,stainless steel and other steel alloy sheet metal fabrication services, contact us, or give us a call at +86 153 8731 8440, and one of our expert associates will assist you. BE-CU is your trusted source for premium sheet metal fabrication services and metal spinning china manufacturer.