Welding is a time-honored and indispensable skill that plays a crucial role in numerous industries, ranging from construction to aerospace. While it might not be the first career choice that comes to mind for many, pursuing a career in welding offers a wealth of advantages. In this article, we will explore five significant benefits of having a career in welding that make it an appealing and rewarding profession.

Strong Job Prospects

One of the foremost advantages of choosing a career in welding is the consistently strong job market. Welders are in high demand across various industries due to their ability to join metals, maintain structures, and fabricate essential components. With the aging workforce and an increasing need for infrastructure development, there is a continuous need for skilled welders. This demand for welders often leads to job security and excellent employment opportunities.

Competitive Salary

Welding can be a financially rewarding profession. Skilled welders often earn competitive salaries, and their income can increase with experience and specialization. Welders who obtain certifications in specific welding techniques or who work in industries with higher safety and quality standards, such as nuclear power or aerospace, can command even higher wages. This financial stability and potential for growth make welding an attractive career option for those seeking financial security.

Versatility

Welders possess a versatile skill set that can be applied in a variety of industries. Whether it’s constructing skyscrapers, building bridges, manufacturing automobiles, or working on pipelines, welders are essential to the completion of countless projects. This versatility allows welders to explore different sectors and diversify their career paths. They can adapt to changing job markets and work on a wide array of projects, adding excitement and variety to their careers.

Hands-On Work

For individuals who enjoy working with their hands and find satisfaction in creating and building things, welding is a gratifying choice. Welders get to see the tangible results of their work every day. They take raw materials and transform them into functional structures or components, which can be deeply fulfilling. This hands-on nature of the job appeals to those who prefer active, practical work rather than a desk-bound, office job.

Opportunities for Creativity and Innovation

Welding is not just about joining metal; it also involves creativity and problem-solving. Welders often face unique challenges that require innovative solutions. They may need to figure out how to create a specific weld joint, repair intricate machinery, or fabricate custom components. This aspect of welding allows individuals to continually learn, adapt, and exercise their problem-solving skills, making it a dynamic and intellectually stimulating profession.

Conclusion

In conclusion, pursuing a career in welding offers a multitude of benefits that can lead to a fulfilling and prosperous professional life. From strong job prospects and competitive salaries to the versatility, hands-on nature of the work, and opportunities for creativity and innovation, welding is a field that provides a rewarding path for those willing to acquire the necessary skills. So, if you are considering a career that combines technical proficiency with the chance to shape the world around you, welding may be the perfect choice for you.

China Sheet Metal Fabrication Manufacturer

Custom precision metal fabrication services. Product specialties include UL® certified NEMA enclosures for various environmental conditions. Capabilities include punching, shearing, laser cutting, bending, machining, press brake forming, and welding. Materials worked with include mild steel, stainless steel, aluminum, brass, and more. Production volumes range from prototype to 10,000 pieces annually. Contract options include discrete orders, blanket orders, quarterly buys, and annual contracts. Value added services include inventory management, rapid prototyping, process development, design for manufacturability, inspection, supply chain management, transportation, and logistics. Industries served include aerospace, automotive, defense, electronic, electrical, entertainment, food and beverage, health, industrial automation, machinery, medical, oil, energy, power, sporting goods, telecommunications, transportation, and more.

using high quality materials

for your sheet metal parts orders

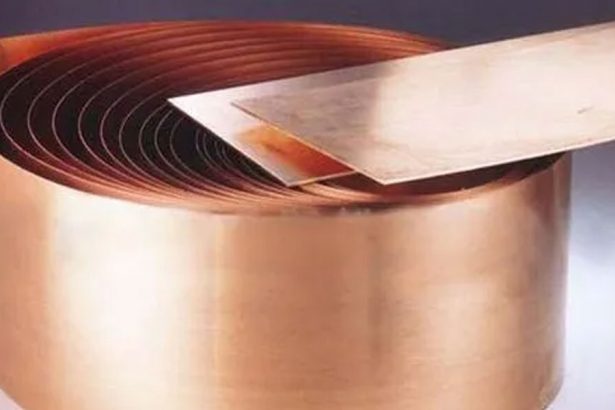

We uses a wide range of material selections for our sheet metal fabrication process. Among our materials are aluminum, stainless steel, brass, magnesium, copper, carbon steel, bronze, galvanized steel, and more. Each material is available in different grades and varieties. Rest assured that all the materials used for your sheet metal parts are durable, corrosion-resistant, long-lasting, rust-proof, wear-resistant, and high-performance. If you want a specific material to be used in the sheet metal fabrication process, don’t hesitate to contact us!

- Carbon Steel

- Stainless Steel

- Aluminum

- Brass

- Copper

- Magnesium

- Bronze

- Galvanized Steel

Why BE-CU is Trusted by 1000+ Clients

Our sheet metal fabrication covers a lot of benefits to many industries, businesses, or projects. Below are the advantages of our services.

- Affordable and Fast Production:We can quickly produce different sheet metal prototypes and final products. KDM offers speedy production while assuring high precision. Our high-volume production also allows us to have cost-effect sheet metal fabrication services.

- Excellent Strength to Weight Ratio:Through our advanced sheet metal fabrication, we can produce sheet metal parts that are lightweight yet durable. We assure high strength, scratch resistance, and corrosion resistance to all produced sheet metal products.

- Wide Range of Materials and Techniques Used:We are experts in different sheet metal fabrication techniques that allow us to produce complex parts with additional intricate features such as notches, slots, holes, etc. Our wide range of sheet metal materials can also withstand electrical, high heat, corrosion, and more.

Online Contact China Precision Sheet Metal Manufacturers

As a direct supplier of precision machined and finished complete components to all segments of the aerospace, semiconductor, automotive, and medical industries, including innovative high tech startups, BE-CU Sheet metal manufacturer is your trusted source for precision sheet metal fabrication services.

To learn more about our aluminum,stainless steel and other steel alloy sheet metal fabrication services, contact us, or give us a call at +86 153 8731 8440, and one of our expert associates will assist you. BE-CU is your trusted source for premium sheet metal fabrication services and metal spinning china manufacturer.