In the ever-evolving world of metal fabrication, reliability is the cornerstone of success. Being the most reliable metal fabrication company is not just about producing high-quality products; it’s about building trust with customers, consistently meeting deadlines, and maintaining an unwavering commitment to excellence. In this article, we will explore the key factors that can help a metal fabrication company earn the reputation of being the most reliable in the industry.

Skilled Workforce

At the heart of every reliable metal fabrication company is a skilled and dedicated workforce. Hiring and retaining experienced welders, fabricators, and engineers is crucial. These professionals bring technical expertise and a commitment to quality that forms the foundation of a reliable company. Continuous training and development programs keep the team updated with the latest industry trends and technologies, ensuring a consistently high level of craftsmanship.

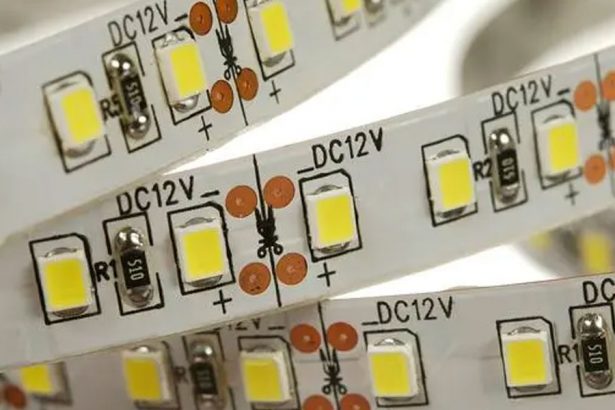

State-of-the-Art Equipment

Investing in modern, well-maintained equipment is essential for maintaining reliability. Advanced machinery, such as CNC plasma cutters, laser cutters, and precision press brakes, allows for increased efficiency and the production of accurate, high-quality parts. Regular maintenance and upgrades are vital to prevent breakdowns and delays.

Quality Assurance

The most reliable metal fabrication companies have stringent quality control measures in place. These measures involve comprehensive inspections, rigorous testing, and adherence to industry standards and customer specifications. Consistency in quality is key to building trust with clients.

On-Time Delivery

Meeting deadlines is paramount in the metal fabrication industry. The most reliable companies prioritize scheduling and project management. They communicate effectively with clients to set realistic delivery dates and proactively address any delays that may arise. Advanced scheduling software can help manage workflow efficiently.

Material Sourcing and Inventory Management

To be reliable, a metal fabrication company must have a robust supply chain management system. This involves sourcing high-quality raw materials, maintaining adequate inventory levels, and ensuring a steady flow of materials to prevent production delays. Efficient material handling and inventory management are crucial.

Adapting to Changing Needs

The market and customer demands are continually evolving. The most reliable metal fabrication companies stay ahead of the curve by adapting to these changes. This includes offering a range of materials, processes, and services to cater to diverse needs. Being versatile and adaptable ensures longevity in the industry.

Strong Communication

Effective communication is fundamental to reliability. Metal fabrication companies must maintain open and honest communication channels with customers, suppliers, and employees. This helps prevent misunderstandings, fosters collaboration, and builds trust throughout the supply chain.

Environmental Responsibility

Sustainability is no longer a buzzword; it’s a necessity. The most reliable metal fabrication companies incorporate eco-friendly practices in their operations. This includes responsible waste disposal, energy-efficient processes, and an emphasis on recyclable materials.

Competitive Pricing

Reliability doesn’t mean being the most expensive option. Competitive pricing is a significant factor in being reliable. A balanced approach to pricing, where quality and value align, ensures that customers receive a fair deal without compromising on quality.

Customer Feedback and Improvement

Continuous improvement is the hallmark of reliability. Listening to customer feedback and acting on it is crucial. The most reliable companies use feedback to enhance their processes, services, and products, providing better value and satisfaction to their customers.

Conclusion

Becoming the most reliable metal fabrication company is a multifaceted journey that combines skilled professionals, advanced technology, quality control, efficient logistics, and a strong commitment to excellence. By prioritizing these key factors, a metal fabrication company can establish a reputation for trustworthiness and dependability, making it the preferred choice for clients in the industry. Reliability is the key to enduring success and growth in the competitive world of metal fabrication.

China Sheet Metal Fabrication Manufacturer

Custom precision metal fabrication services. Product specialties include UL® certified NEMA enclosures for various environmental conditions. Capabilities include punching, shearing, laser cutting, bending, machining, press brake forming, and welding. Materials worked with include mild steel, stainless steel, aluminum, brass, and more. Production volumes range from prototype to 10,000 pieces annually. Contract options include discrete orders, blanket orders, quarterly buys, and annual contracts. Value added services include inventory management, rapid prototyping, process development, design for manufacturability, inspection, supply chain management, transportation, and logistics. Industries served include aerospace, automotive, defense, electronic, electrical, entertainment, food and beverage, health, industrial automation, machinery, medical, oil, energy, power, sporting goods, telecommunications, transportation, and more.

using high quality materials

for your sheet metal parts orders

We uses a wide range of material selections for our sheet metal fabrication process. Among our materials are aluminum, stainless steel, brass, magnesium, copper, carbon steel, bronze, galvanized steel, and more. Each material is available in different grades and varieties. Rest assured that all the materials used for your sheet metal parts are durable, corrosion-resistant, long-lasting, rust-proof, wear-resistant, and high-performance. If you want a specific material to be used in the sheet metal fabrication process, don’t hesitate to contact us!

- Carbon Steel

- Stainless Steel

- Aluminum

- Brass

- Copper

- Magnesium

- Bronze

- Galvanized Steel

Why BE-CU is Trusted by 1000+ Clients

Our sheet metal fabrication covers a lot of benefits to many industries, businesses, or projects. Below are the advantages of our services.

- Affordable and Fast Production:We can quickly produce different sheet metal prototypes and final products. KDM offers speedy production while assuring high precision. Our high-volume production also allows us to have cost-effect sheet metal fabrication services.

- Excellent Strength to Weight Ratio:Through our advanced sheet metal fabrication, we can produce sheet metal parts that are lightweight yet durable. We assure high strength, scratch resistance, and corrosion resistance to all produced sheet metal products.

- Wide Range of Materials and Techniques Used:We are experts in different sheet metal fabrication techniques that allow us to produce complex parts with additional intricate features such as notches, slots, holes, etc. Our wide range of sheet metal materials can also withstand electrical, high heat, corrosion, and more.

Online Contact China Precision Sheet Metal Manufacturers

As a direct supplier of precision machined and finished complete components to all segments of the aerospace, semiconductor, automotive, and medical industries, including innovative high tech startups, BE-CU Sheet metal manufacturer is your trusted source for precision sheet metal fabrication services.

To learn more about our aluminum,stainless steel and other steel alloy sheet metal fabrication services, contact us, or give us a call at +86 153 8731 8440, and one of our expert associates will assist you. BE-CU is your trusted source for premium sheet metal fabrication services and metal spinning china manufacturer.